Free Shipping

Telescoping Truck Camper Plans

Build a Low Profile Slide In Camper for Truck Travel

|

Telescoping Truck Camper Plans

Build a Low Profile Slide In Camper for Truck Travel

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these vintage Telescoping

Truck Camper Plans with 15 Pages of Enhanced and Enlarged Figures

and Illustrations and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

|More

Vintage Trailer Plans|

|

|

|

|

Big Inside, Camper Telescopes

for Travel

Concealed winches and cables stretch it out again

to hold four people at the campsite.

|

| You will be proud to call this sleekly finished camper

your home on the road. Prefinished hardboards panels give the interior

a warm atmosphere, as well as one that's easy to keep clean. Aluminum siding

and fiberglass-batt insulation ensure that the interior stays warm in another

sense, too. Or cool, in desert heat.

There are plenty of cabinets and lockers to hold your

travel equipment, yet lots of room is left for the custom installation

of a sink, icebox, stove, and portable toilet.

For sleeping, the dinette table drops down to form part

of a double transverse bunk. Shelves fold out to form a strong upper berth

for another two people.

And the best news: It all costs you well under $1000 to

build. Thet ups the enjoyment.

- W. A. Flanagan |

|

|

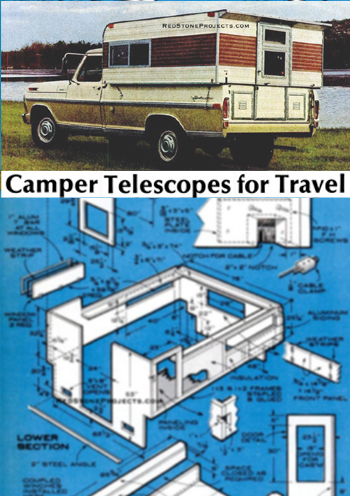

Low profile of this camper when telescoped offers

less wind resistance. Your pickup will pass up more gas stations and feel

crosswinds less, too, than if carrying a cab-over model. Cranked up for

the night, the camper boasts 74" of headroom. With built-in stove, icebox,

cabinets, sink, and toilet, it still sleeps four. You can customize the

interior to suit your taste.

|

Inside the Telescoping Camper

By JIM ABBOTT

|

|

|

|

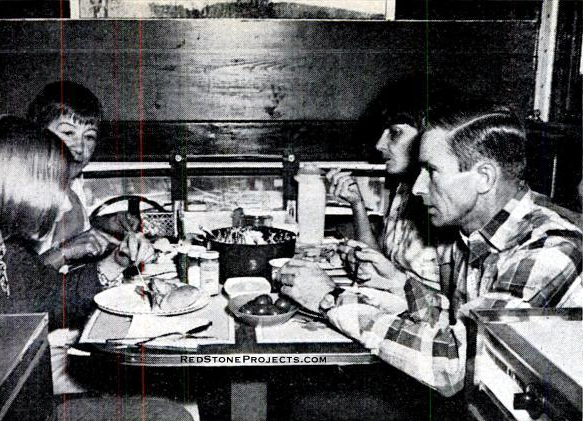

There's plenty of room to feed and sleep two couples,

and stow their gear. The camper offers all the comforts of your home -

and its construction is similar.

|

|

|

Eating and sleeping space inside the raised top

accommodates four people - with a cozy fifth optional.

|

|

|

|

|

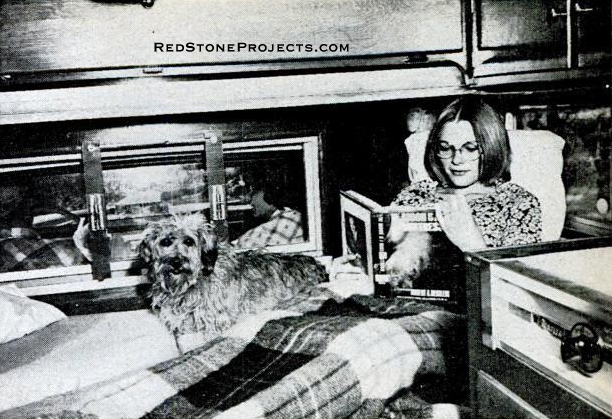

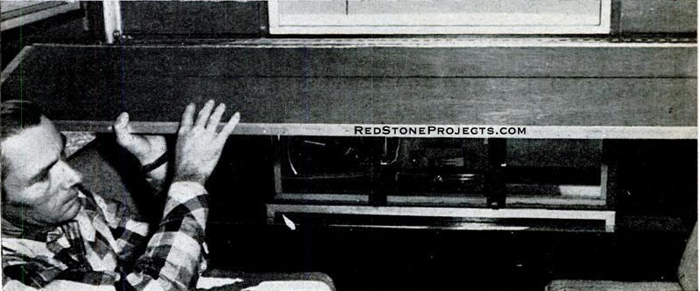

Front edge of the dinette table folds up for access

to seats. Lower berth, occupied by author's daughter at right, consists

of seat backs, folded down, with space between them bridged by the lowered

dinette table.

|

|

| Interior walls are 1/8" hardboard wall paneling, which

gives you a wide choice of prefinished colors and textures. Outside, the

camper is sheathed in aluminum house siding (also pre-finished in colors)

to save you painting and maintenance. The two layers sandwich between them

an open frame that you can insulate with fiberglass batts. |

|

|

Wide plank over the far end of dinner table is

actually three hinged planks which fold out, as at right, to form an upper

berth. Upper is wide enough for two children or one adult. Floor space

is ample for another adult on an air mattress.

|

| Plan Ahead

Dimensions given here are for the camper I built to fit

in a 1969 Chevrolet pickup. It should fit in many other models, but measure

your truck box before starting and adjust the plans if necessary. (You

could even adapt the telescoping feature to a small travel trailer.)

Construction starts, logically, with the foundation: the

floor pan. It's mostly 3/4" plywood, nailed and glued at the joints. Here

again you want to plan carefully - some of the interior furnishings can

serve double duty as part of the floor pan. The sides of the sink and icebox

replace the 8 1/2" by 11 1/4" end panels, keyed No. 3 on the construction

drawing.

With the foundation completed, check the dimensions for

agreement with plans and truck bed. Then, build your walls to fit this

floor.

One of the best ways I've found to make the wall frames

is to cut out the framing pieces and lay them on a flat surface. Apply

white glue to the joints and fasten with pointed staples. Turn the frame

over, carefully, and staple the other side, the same way.

Framing is 1" stock (3/4" finished thickness). Most pieces

can be 2" wide, but allow extra for corners, window posts, and an on. Use

a good fir or pine, preferably kiln-dried. |

|

| |

Get a restored copy of these vintage Telescoping

Truck Camper Plans with 15 Pages of Enhanced and Enlarged Figures

and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

Figure

1. Construction and Dimensions

|

|

| Frame design isn't critical, so you may want to rip boards

to widths different from those indicated. At the ends, and particularly

at the rounded comers of the upper section, 3/4-ply can reduce the complexity.

Immediately apply the interior panel, using white glue

and nails or contact cement. Note that the side panels are right and left-handed:

Don't make two of one kind. Cut out window or door opening after the panel

is in place. Leave the insulation and siding for after assembly.

Curve the front ceiling panel by steaming it (a steam

iron will do) until it will follow the bend. Then fasten with glue and

3/4" screw nails to the underside of the roof frame. Drill holes through

frame for wires to the lights before adding the larger ceiling panels.

Wires to the upper section pass through a 3/4" flexible

tube hanging from the right-rear comer of the ceiling. A weight draws it

into a space behind a lower cabinet as the upper section telescopes down. |

|

|

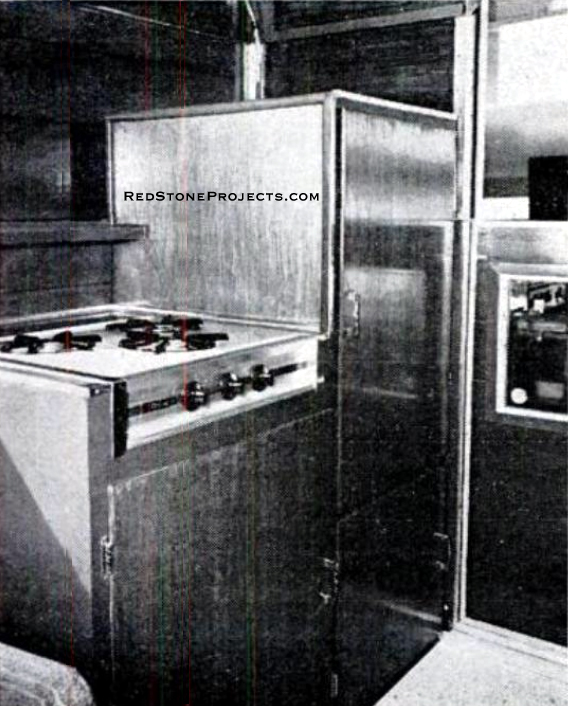

Drop-in stove tops off cabinet that also holds

icebox below. Big corner cabinet holds bulky items like sleeping bags.

|

| Lifting Mechanism

A pair of boat trailer winches on the left side of the

lower section draw in two 1/8" cables each. These cables pass over 3" pulleys,

high in the lower section, to the bottom corners of the upper section of

the camper.

As the cables wind up on the drums, they raise the top.

Two ball bearings in each corner of the lower section project out about

3/8" to keep the sections from binding.

The right-rear cable passes under the door through a rabbet

in the threshold. The prototype of this camper (shown in the photographs)

had variable pulleys and turnbuckles to level the top by adjusting cable

length. It turns out simpler and just as easy to move the clamps on the

ends of the cables.

Another possibility is to route the front cables to the

rear winch; but you'd lose the safety advantage (double lock) of the second

winch. |

|

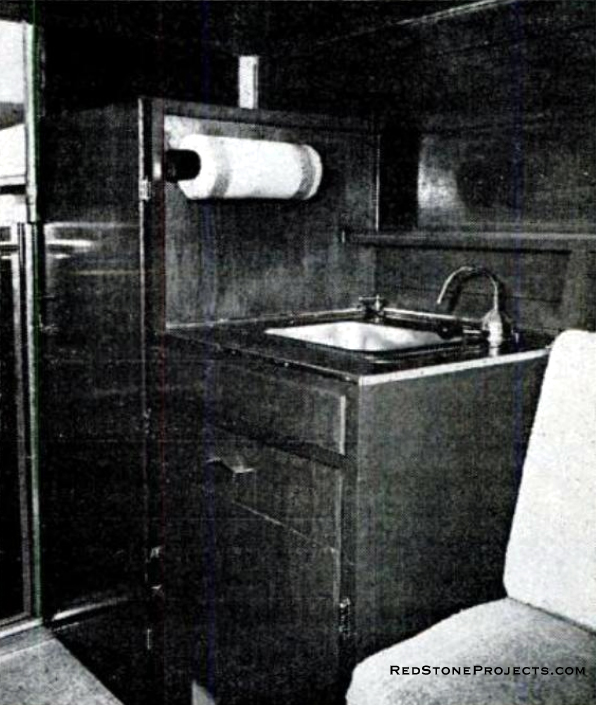

Sink and water tank share the section in front,

with storage

to spare. Clothes hang neatly in wardrobe.

|

| Before assembling any panels, make sure the pulleys,

bearings, and other hardware fit in their notches. When satisfied, assemble

the lower-section wall panels on the floor pan.

Add the aluminum siding, to the lower section only, after

filling all voids in the frame with 1" insulation. Don't side the upper

section until after it's been placed over the lower section - too much

weight for you to lift.

Cut siding (including window openings) to the exact dimensions

of the frames and nail, at the edges only, with 3/4" screw nails. Working

with the aluminum panels isn't difficult after a little practice. They

cut easily with metal snips, but here's an easier method:

Mark intended cuts with a felt-tipped pen, tracing the

outline of a frame as the siding is held against it. Scribe these lines

with a sharp knife or razor knife. Bend the metal away from the cut, then

back. It will pop apart, leaving a clean cut. |

|

|

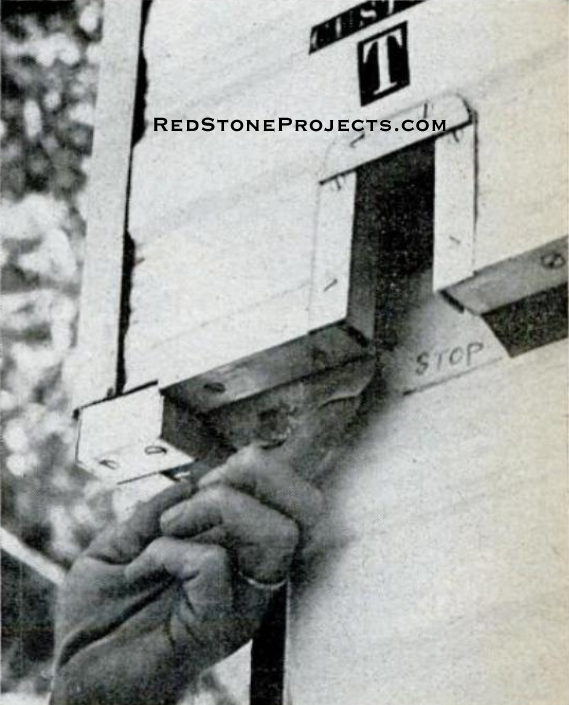

Rubber weather seal all around the edge of camper's

upper section keeps wind and bugs out. Notch clears winch handle.

|

| Windows and exterior trim come next. Seal all joints

with waterproof putty. Drill through front and rear panels for the pulley

axle bolts. Put in winches and lifting cables, leaving 3 feet of cable

extending beyond each corner pulley.

Before installing siding on the top section, get some

friends to help place it over the lower section. Use 2" fiberglass batts

in the roof. Cover the roof and front with one piece of roof roll.

Raising The Roof

The upper section should now be resting with its lower

edge about 1/4" below the side panels of the lower section. The upper cabinets

support the top section when they bear against the tops of the lower wall

panels. |

|

|

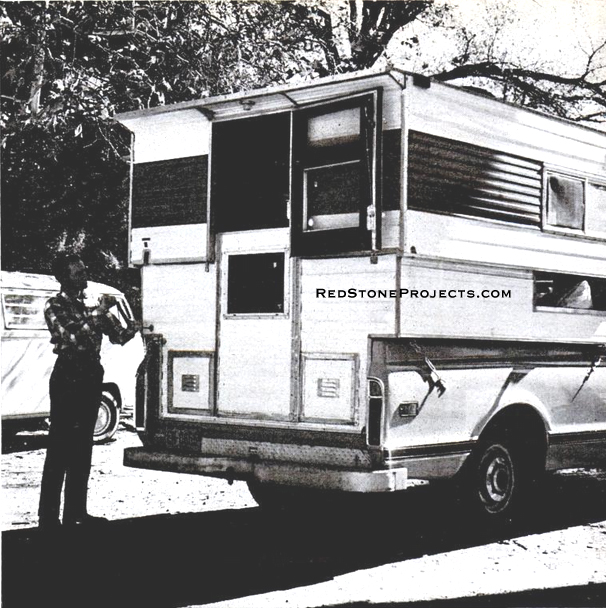

Camper jacks work in the normal way, just make

sure that they bear on the lower section, and not the upper one.

|

| Thread the cables through the clamp plates and weight

them (a brick is fine) as you slowly crank the winches until 18" of cable

is on the drums. Install a clamp on each cable; keep the four at equal

distances from the plates.

Continue raising until the inside height is no more than

74", then lower about 6". Lock the winches. This is a good position to

check for even cable length: Measure between lower panels and ceiling.

Variations up to 1 inch don't affect operation. Any more and you should

lower the top all the way and reposition the cable clamps.

Finish off with the sealing strip around the upper section,

corner molding, wiring, and the doors. The doors can be solid ply, or built

up like the walls. Leave room for weather strips and the 1-inch-wide piano

hinges. Lock hardware will depend on personal preference.

The interior shown in the photographs is based on a 1969

Chevrolet pick-up. You may want to try an entirely different layout. If

so, remember that the rear wheel wells intrude on the truck box, to the

camper is narrow in front.

Keep in mind that interior accommodations could have

been constructed even before the walls were added to the lower section.

Or you can build them in last.

Away We Go

To put the camper on your truck, first winch up the top

and block it up (with 3" blocks on interior ledges) no the upper section

will clear a pair of standard camper jacks. As with all jacks, exercise

great care. Back the truck under the camper - carefully. Lower the camper

and fasten it to the truck bed. I used two bolts through the front of the

floor and four turnbuckles outside. Remove the blocks, hook up the electricals,

and that's it.

You're ready for the road. |

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|