Free Shipping on All U.S. Orders

All Orders Processed on a Secure Server

Build Your Own 3-4 Berth Caravan

Plans for a DIY Lightweight Vintage Camping Trailer

Building Your Own 3-4 Berth Caravan

by H.C. Piggin

|

| AFTER an initial "bedding-down" run of about 150 miles,

this van accomplished well over 1,200 miles of touring during August, 1958.

This included negotiating the usual bumpy sites, longish runs over granite

setts and very much second-class roads. Nothing was shirked in an effort

to find weaknesses, but apart front a little easily cured trouble due to

under springing, and a puncture, the longer journeys were quite uneventful.

The van towed well, and most of the time was hardly noticeable behind the

car, an early Vauxhall Wyvern.

In general, the construction is orthodox, although the

wooden main bearers are no longer in commercial fashion in these days of

cheap rolled channel-steel; however, they were chosen here to save weight

and to facilitate home construction. |

|

| Although throughout the accent is on ease of construction,

careless and shoddy work is inadmissible; a faulty joint or loose screw

may well spell danger and disaster to the driver and other road users.

A high degree of skillful craftsmanship is not necessary, ordinary careful

work being quite enough, but the home builder who is doubtful of his work

on any point will do well to consult tradesman, particularly over the road-worthiness

of the undercart.

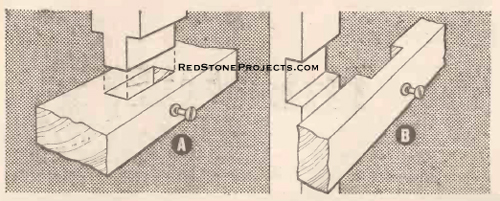

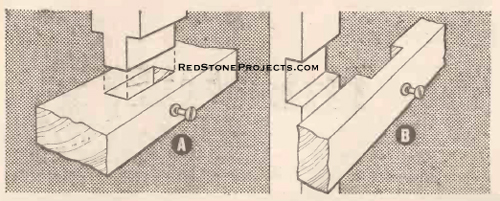

So far as the woodwork is concerned only two joints -

the halving joint and the plain mortise-and-tenon joint are needed. An

hour or so spent in practicing these in scrap timber will be well worth

while. (See Fig. 8.)

Most of the metalwork consists of cutting angle-iron,

drilling it, and bolting it together ready for welding. Such welding as

there is should be carried out by a competent engineer.

Proprietary parts have been kept to a minimum so far as

possible in order to keep costs down. Apart from small fittings of a general

ironmongery order, only the corner jacks and the all-important ball towing-hitch

must be purchased. If expense is no object, then such items as proprietary

window frames, sink-unit and Calor-gas fitting will save time and improve

the van quite a lot. However, some modification of the plans shown here

will be necessary to accommodate the stock sizes of such fitments, they

should thus be carefully thought about before building begins. Indeed,

an intensive study of caravan periodicals and accessories catalogues is

an essential preliminary to any caravanning venture.

There is some prejudice against "non-proprietary", or

"home-built" vans, as so many of these are badly designed and worse constructed.

Many site-operators forbid such vans entirely, whilst others insist on

a

superficial inspection. It is as well, therefore, to ensure that only the

best is good enough, so far at outward appearance is concerned. |

|

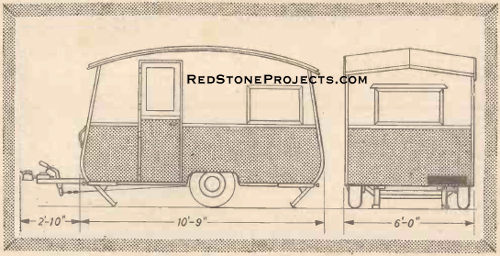

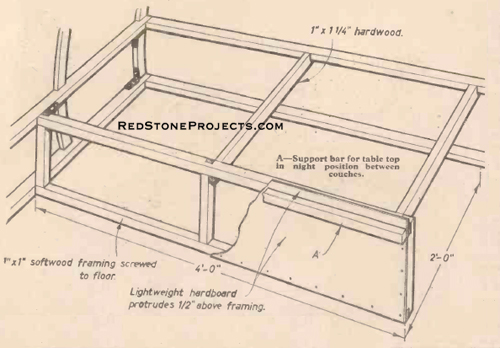

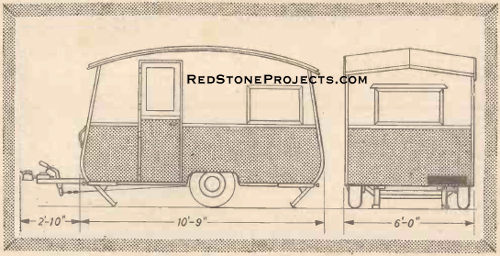

Figure 1. Side and rear views of the completed

caravan.

|

|

|

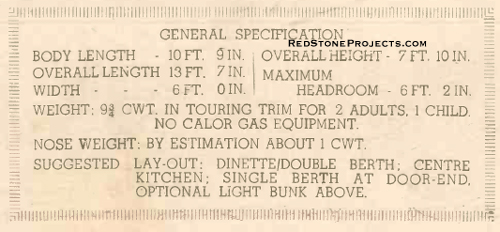

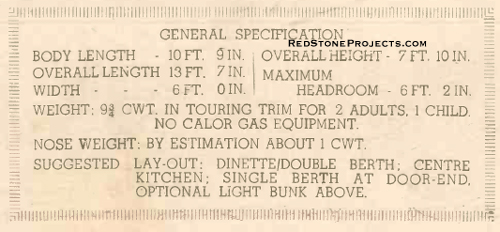

Caravan General Specifications

|

|

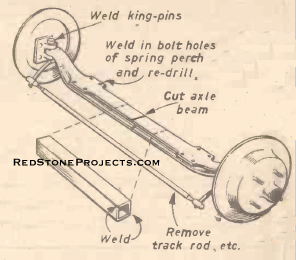

| The Axle and Wheels

Only sound work will suffice in the chassis. A poorly

made chassis will, apart from being a possible danger on the road, be a

constant source of trouble in towing, leading to all sorts of misbehavior

on the part of the van, which makes driving sheer hard work all the time.

Some home constructors may prefer to save time by purchasing

a ready-built chassis, but this will run to considerable expense.

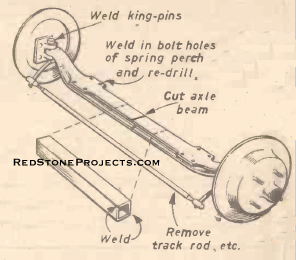

The wheels of the caravan described here were adapted

from an old car front axle as follows.

First, all extra metal in the form of track-rod, shock

absorbers, etc. is removed. The wheels are then lined up with a very slight

toe-in, and the king-pins are welded-up solid.

The axle is then cut in the middle and extended to give

a track between tire centers of 5ft. 6in., by boxing across the center

with two pieces of angle-iron welded together and to the axle ends. (Fig.

2a.)

For steady, stable towing a wide wheel-base is necessary,

with as great a distance as possible between the springs to avoid "top

roll". (Fig. 2b.) |

|

Figure 2a. Principal work on the axle.

|

|

| The Springs

These are removed and stripped. They should be cleaned,

reset and rebuilt with an extra leaf or two to a total of 9 in. X 3/16

in. The longer the springs the better.

As they are usually set at an angle on car front wheels,

the old bolt holes on the perches should be welded-in, and new holes drilled

so as to line up the springs at right-angles to the axle. The minimum distance

between the springs should be 3 ft. 2 in. If the spring perches can be

shifted wider apart it is certainly desirable to do so, but this may not

be possible on cranked axles.

On straight axles, the springs can be reattached below

the axle (underslung), so that a few inches of height reduction are obtained.

A low center-of-gravity is useful for stable towing.

It will be as well to strip and regrease the wheel-bearings

and to attend to the brakes (which should be of the cable-operated kind)

to see that the linings are good and the action free in operation.

Tires need not be new, but should certainly not be smooth.

In spite of rumors to the contrary, caravans do get punctures and bursts,

and as no "spare" is carried as a rule, such mishaps can be embarrassing

and involve considerable delay!

The axle and brake drums can be smartened up with a coat

of bitumen paint, and the springs can be sprayed with penetrating oil. |

|

Figure 2b. The caravan Undergear.

|

|

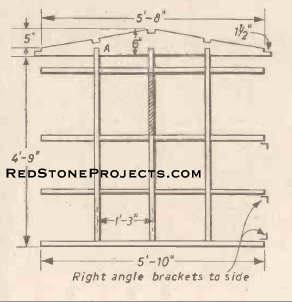

| Main Chassis Bearers

Those consist of two soft. 10 ft. 6 in. lengths of 3 1/2

in. X 2 in. straight-grained prime ash. They must be free of all knots

and blemishes, and it is worth paying a little extra to get the best timber.

The size given is quite the minimum, and due allowance for planing must

be added.

After shaping, the bearers are bolted on to the springs,

using 3/8 in. diameter coach bolts with extra nuts as lockouts. (Fig. 3.)

It is important to mount the rear scroll with its shackle high, remembering

that it will settle under load. The bearers should be parallel to each

other, and should be braced apart until the flooring is secured. They should

also be levelled and supported on blocks until this is done. |

Get a restored copy of these vintage Build Your Own

3-4 Berth Caravan with 23 Pages of Enhanced and Enlarged Figures

and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

Figures

3, 4 and 5. Details of the main bearers, the floor assemble and tow. |

|

The Floor

In this design the floor is an integral part of the chassis.

It consists of 3/4 in. thick tongued-and-grooved deal boards, screwed on

to the ash bearers with 1 1/2 in. No. 9 steel screws. The boards must be

pulled

up tight together, and the screws inserted diagonally staggered, not in

straight rows. (Fig. 4.).

When all the flooring has been fitted according to plan,

the ends of the floorboards should by levelled and the 1 1/2in. X 1 in.

outrigger supports glued and screwed up tight under the ends of the boards.

At this stage, the complete floor and axle can be fairly

easily man-handled by four or five men. It should be turned over for ease

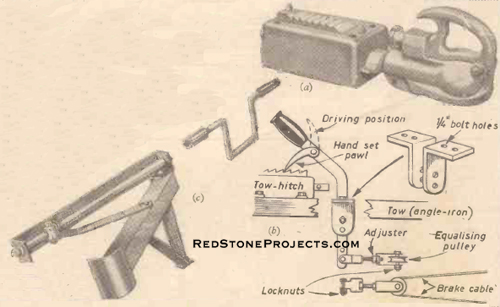

of fitting the ironwork - tow and corner jacks (Fig. 5). At this point,

too, the opportunity should be taken to apply several coats of bitumen

point to the underneath parts.

With the floor right way up, it can be levelled on its

jacks to await the mounting of the bodywork frames.

|

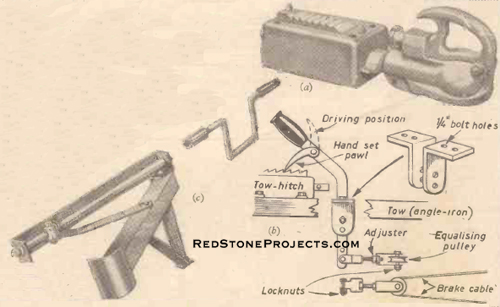

Figure 6. (a) "Ball" type of towing hitch; (b)

Hand brake; (c) Brace operated van leg.

|

|

| The tow-hitch is bolted on to the towing bar with high-tensile

bolts. These should be pulled up a little at a time, checking the over-ride

action occasionally to see that it remains free. If one bolt is overtightened

it is possible to warp the casing of the hitch and so cause the action

to bind (See Fig. 6a). The position of the brake-lever is fairly critical,

and should be checked carefully (Fig 6b). The brakes are connected-up and

adjusted so that they come on smoothly as the over-ride is forced back.

Final adjustment is best left until the van is ready for the road. The

brakes should never lock the wheels completely on the over-ride but, of

course, they must be fully applied on hand-pull.

Body Frames

All body frames are built from prime ash. The joints consist

mainly of straightforward mortise and tenons at "T"-junctions, and cross-halvings

at "through" points. All are glued with a waterproof resin glue, and secured

additionally with a 3/4 in. long No. 8 countersunk steel screw.

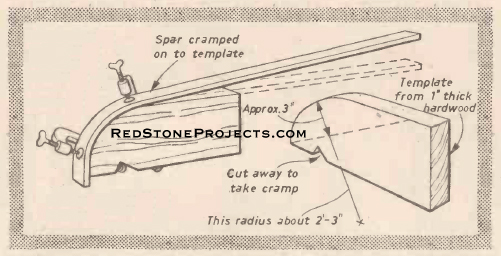

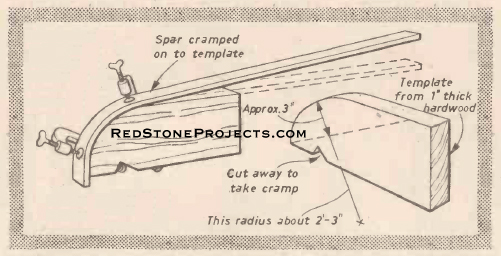

The end bends are made by soaking suitable lengths of

timber in a water-butt for at least 48 hours. Each is then cramped on to

a 1 in. thick oak board shaped to the required curve, and is left to dry

(fig 7.). Up to a week may be required to achieve the desired curve. It

is important that all ten bends must match up, and as they are made, they

should be lashed together and stored carefully on end until required.

Except for the spacing of the upright to allow for the

door, both side frames are identical.

It is as well to cut all timber to length and number each

piece as indicated in Fig. 9a. Then all parts which are to be of the same

dimensions can be placed together and marked-out in one operation, thus

ensuring identical accuracy for all floor and middle lengths, uprights,

corner bends, etc.

Note that the corner bends are fitted into mortises cut

at the necessary angle in the floor-lengths; the surplus is removed after

fixing, which is easier than trying to cut true "bridle" joints as such.

Assemble all joints temporarily to check their fit and

the truth of the whole framing. Then check the side frames together to

see that they are identical and quite flat.

The end flames shown in Fig. 9b present little difficulty.

Again, every care most he taken to ensure that they are identical with

each other. |

|

Figure 7. Method of making the end bends.

|

|

| Assembly of Frames on to Floor

The completed side frames are coach bolted into position

on the floor edge; the bolts, of course, pass right through the end supports

under the floorboards. The frames will require strutting temporarily to

prevent them from waving about.

The end frames are similarly bolted down.

The tops of the side-frames have to be nipped in" two

inches on to the headboards of the ends This places the side under slight

tension, and helps to give rigidity and stability.

The middle spars of the end frames are attached to the

corner bends with small, right-angle brackets, as can be seen in Fig. 9b.

This saves cutting an awkward joint which might weaken the bend. |

|

Figure 8. (a) A simple through mortise-and-tenon

and (b) cross-halving.

|

|

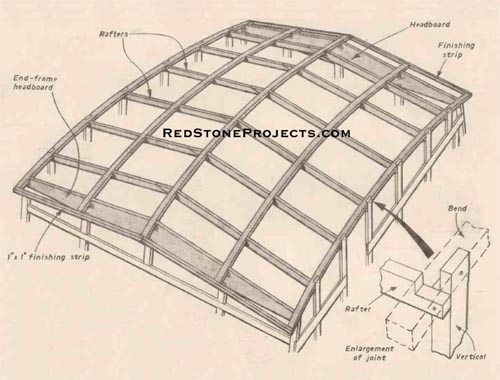

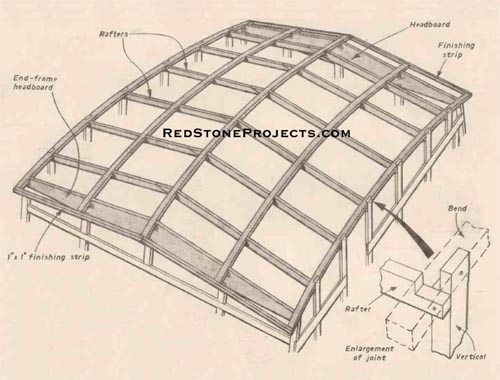

| The Roof Framing

The three roof bends can have their curves shaped whilst

the sides are being made, by wetting them and bracing them over a pile

of bricks. It is not essential to do this as the roof curve is quite a

small one, but it does help to reduce the tension.

The rafters are spliced to exactly the same angle as that

of the end frame heads (Figs. 9b and 10). Then the ends of the rafters

are halved and screwed on to the side frame roof bends. The rafters should

be braced temporarily at their centers until roofing is completed.

The roof bends are set down into their sockets, being

held with cramps until the screws are put in. It is as well to offer everything

on screws only at first, leaving the final gluing until all adjustments

have been made. |

Get a restored copy of these vintage Build Your Own

3-4 Berth Caravan with 23 Pages of Enhanced and Enlarged Figures

and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

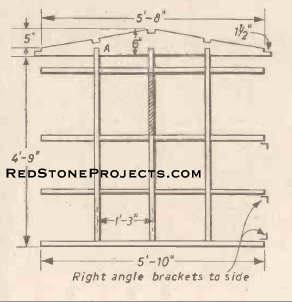

Figure

9a. Details of the side framing.

|

|

Finally, the ends of all rafters are faired off the sides.

The ends of the roof bends are cut level, and are joined across with finishing

strips of 1 in. X 1 in. soft wood, glued and nailed into place (Fig. 11).

The rafters and the center roof bend, together with all

other protrusions on the roof, must all be faired-off to the main run of

the curve and slopes so as to get the maximum surface for setting down

the roof surface.

|

Figure 9b. The end frame.

|

|

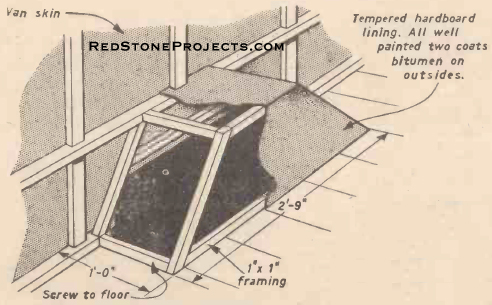

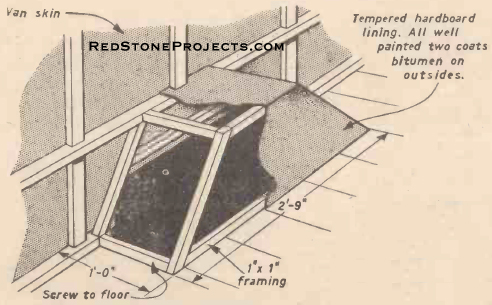

| Wheel Boxes

It is useful to build these in before the van is skinned.

The construction is quite simple and shown in detail in Fig. 12. |

|

Figure 10. Splicing rafters to suit slope of end

frame headboards.

|

|

| Skinning the Caravan

At this stage the Pram appears unduly fragile and not

very rigid, but the application of the skin will soon correct this.

On the van shown, the skin is 1/8 in. thick tempered hardboard,

which is entirely weatherproof in itself and has a long life.

Hints About Hardboard

A few general points about the fixing of hardboard will

be found useful. Each board should be well soaked with water for at least

48 hours; the backs should be sprayed quite wet, and the boards stored

back-to-back. This treatment, together with adequate fixing battens (the

recommended distance is 1 ft. 3 in., but the 1 ft. 6 in. of the framing

seems adequate), will help to prevent distortion. The best nails to use

are the special hardboard nails with square shanks and "lost heads" made

in coppered steel. They should be used at 3 in. to 4 in. intervals, and

fixing should begin at the middle of each panel, working outwards to the

edges and corners, making sure that all kinks are removed and that the

work lies flat. Panels should not butt up tight against each other; a gap

of 1/8 in. is permissible.

On the caravan, all hardboard edges should be bedded on

to a good layer of mastic sealer, and all points filled with this substance

well pressed home.

Before painting, the hardboard should be primed with special

hardboard sealer paint. All nails should be driven flush or a little below

the surface. All holes and blemishes should be stopped up after priming

(putty will do) and rubbed down well.

Bearing in mind these general points, the skinning of

the caravan will present few problems. The van shown was skinned with large

surfaces for quickness, cut from 12 ft. X 4 ft. sheets. Apart from some

waste involved at the curves, this method has shown no drawbacks, although

the use of smaller sheets may be more economical. However, the large joint-free

surfaces are certainly neat and watertight.

The Sides

The bottom side panels were put on first, having been

offered to the framework for careful marking out. The top sides followed

the windows being cut out beforehand. Then the ends were dealt with, being

allowed to overlap the sides as the corners. |

|

Figure 11. General view of roof framing.

|

|

| The Roof

The roof was put on in two pieces, these being offered

to the job, marked off and cut. The first piece is fairly easy, being adjusted

to the middle of the center roof bend first and trimmed off at the edges

after fixing. The second piece has to be adjusted to give a neat joint

against the first at the center. This is best done by trial and error;

the hardboard is easily cut and planned. Again, it is better to allow the

roof to overhang at the eaves and to make this tidy after fixing. All sharp

corners should be glass papered off, and all nails made flush before applying

the roof canvas.

This is plain canvas and need not be of exceptional quality.

It should be 4 yds. long and 6 ft. 6 in. wide. From one end strips 4 in.

wide are cut, which are used first to seal the central joint, and any others

if the roof has been put on in smaller sections.

The canvas can be fixed either with an adhesive, or bedded

down on to wet paint. A liberal coat of either is applied along the joints,

and the canvas strips are pressed firmly into place. When the sealing strips

are dry, the main canvas is rolled and placed conveniently at one end of

the roof. An area about 1ft., or so, wide at a time is painted with adhesive

and the canvas is unrolled on to is, being pressed down and smoothed to

remove wrinkles, before proceeding with the next area. The canvas should

not be stretched tight. as it may split as it dries.

Any surplus canvas is trimmed off so as to leave an overhang

of about 1 1/2 in. This is turned under and pressed on to fresh adhesive

at the eaves, being fixed with copper tacks at 3 in. to 4 in. intervals.

At the ends the canvas is taken right under the overhang, and is glued

and tacked into the finishing strips.

When dry, the canvas is given a priming coat of lead-based

paint as soon as possible. This may be followed with as several coats at

the time of painting the whole van. |

|

Figure 12. Simple construction of the wheel box.

|

|

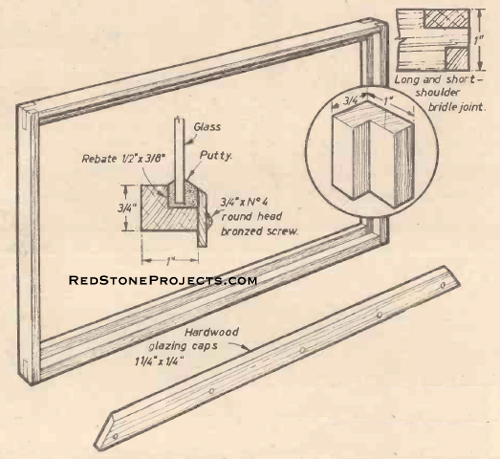

| The Windows

All surplus spars across door and window spaces should

be cut away, and the inner edge of the spaces rendered smooth.

The spaces for the door and opening-windows should be

primed and any holes stopped. They may then be undercoated to help seal

the hardboard. One excellent finish for these edges is to glue strips of

Formica along them. |

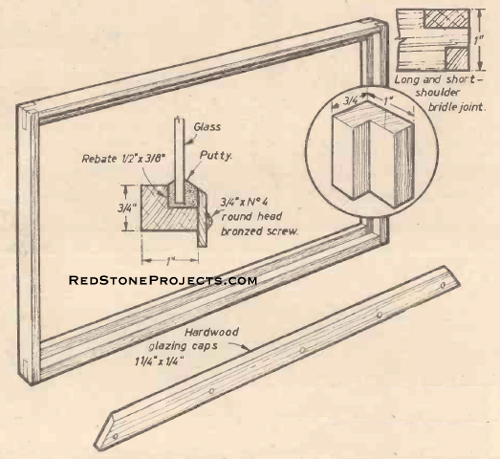

Figure 13. Construction details of the windows.

(Fixed windows may be a little lighter in section.) |

|

| After finishing the spaces, they should be most carefully

measured and the making of the doors and windows put in hand.

The windows are simple enough, being plain, rebated soft-wood,

with dowelled bridle-joints at the corners, as shown in Fig. 13. The hardwood

glazing strips are fixed with raised-head bronzed screws, using mitered

corners as shown. It is well to make up the whole window before glazing.

This is done with 24 oz. glass on ordinary linseed putty, and it is necessary

to prime all parts where the putty is going.

The fixed-window frames are nailed into place before glazing,

and the opening-windows are best hung without the glass. If the frames

have not been made too tight little difficulty will be had with fitting

these.

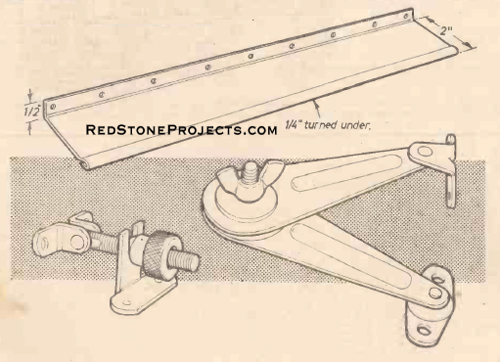

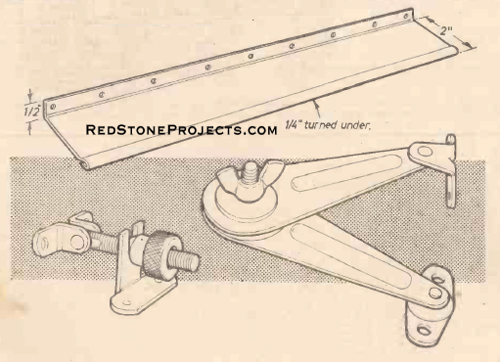

Each of the opening windows requires two friction stay

sets and at least one screw-up type of window-fastener of the type shown

in fig. 14 |

|

Figure 14. Window fittings. Shown here are a storm

pelmet for opening -windows made from 20 s.w.g. aluminum, a window fastener

and a friction stay -set.

|

|

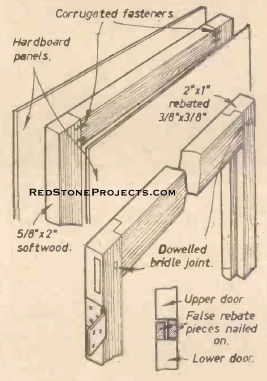

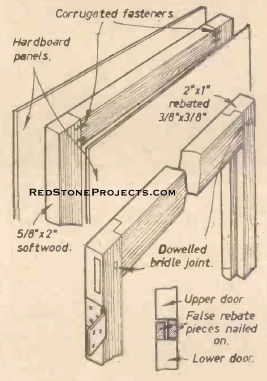

| The Door

The bottom door is a plain panel of hardboard on softwood

framing. The upper door is glazed and is made from rebated softwood with

dowelled mortise and tenon joints. Both are hung on ordinary steel flap

back hinges which are allowed to protrude about 1/2 in. so as to swing

the doors clear of the van. The middle joint between the doors is made

up by false rebates nailed on (Fig. 15). |

|

Figure 15. Details of the paneled lower door and

the glazed upper door.

|

|

| Exterior Fittings

The "J"-type roof guttering is screwed on to the roof

canvas overhang, being set on to half-dry paint.

The aluminum storm-strips over the opening windows are

similarly fixed, together with those at the doors. |

|

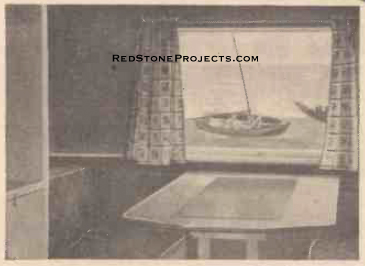

Figure 16. A photograph of the interior of the

author's caravan.

|

|

| Ventilators are fitted to the outside, one over the sink

and cooker unit, and one in the wardrobe. The positioning of these will

depend on the interior layout, of course, and must be plotted carefully.

It is as well to drill small holes through the hardboard at the corners

of the vents so as to plot the position of any extra fixing battens of

1 in. X 1 in. softwood which will have to be glued on to the interior of

the skin. The surplus skin between the fixings is cut away with a pad saw. |

|

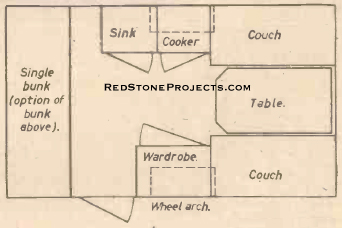

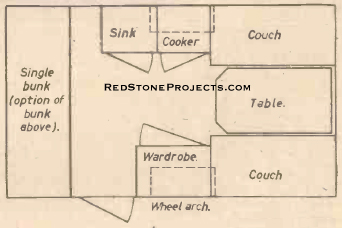

Figure 17. Suggested typical layout for 3-4 berths.

Couches and table make double bed. There is space for storage under couches

and bunk.

|

|

| The van should be primed and undercoated. However, it

is best to leave the final gloss until the van has been given a short tow

to shake things down.

all bright aluminum waist and corner moldings are screwed

on to wet undercoating any surplus being carefully rubbed off. Naturally,

the more care that is taken over the painting, the more professional will

be the final result. Plenty of patience, thin coats and good rubbing-down

in between will give the best results. |

|

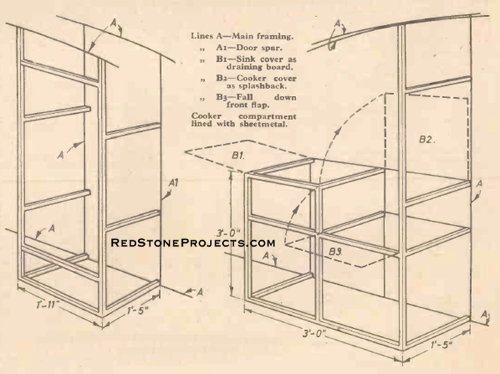

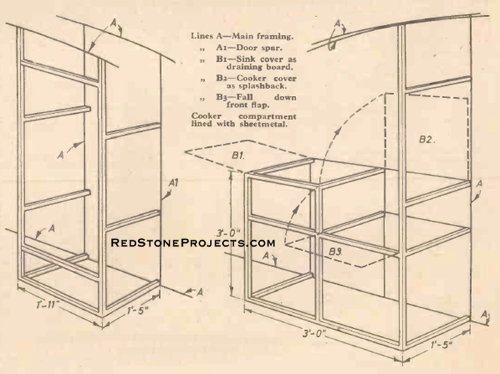

Figure 18. Framing details of the wardrobe and

sink/cooker unit.

|

|

| A number-plate, it should be pointed out here, is legal

necessity. Rear lights and reflectors are needed only if the van is towed

at night. And whilst on the subject of the law, it is as well to check

on the car insurance policy to make sure that the "third party" is valid

when a caravan is attached to the car. Wing mirrors on the car are also

necessary if a clear view through the front and rear van windows is not

obtained from the driving seat. |

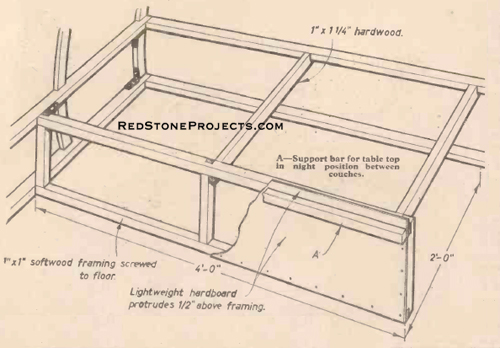

Figure 19. A dinette couch. Other couch and bunk

are of similar construction. Joints are halved, glued and screwed and the

1/8 in. hardboard top rests on

main van spar and front framing.

|

|

| The Interior

No one interior layout is entirely satisfactory to every

enthusiast, and as this part of the van is so dependent on personal choice,

only general guidance is given (Pics. 16 to 20).

In this small van with its light construction, the wardrobe

is essentially part of them main structure and helps to brace the roof

as also does one side of the cooker unit. It is desirable that both of

these should be kept fairly central, within six inches or so one way or

the other. The dimensions otherwise are not critical.

All furniture is permanently fixed and is built on to

existing mainframes wherever possible to save weight. Softwood framing

1 in. x 3/4 in will be found to be adequate for most pieces, being paneled

with lightweight hardboard (nominally 1/16 in. thick or 3 mm. ply). |

|

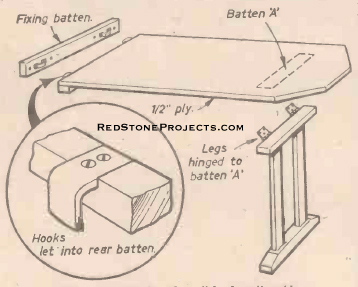

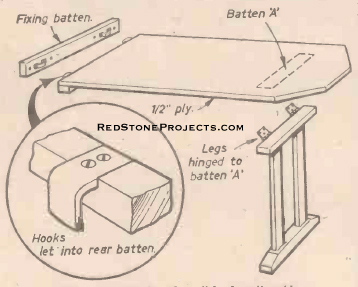

Figure 20. Details of a ""hook-on" table.

|

|

| Where weight is carried, as on seats and beds, the longest

unsupported run of framing is only 24 in., and some reinforcement of cross

members is necessary.

Doors are framed-up in the simplest possible style, use

being made of corrugated box-fasteners rather than complicated joints.

Walls are lined with 3 mm. ply; one of the pinky colors

such as Japanese lauan, or gaboon looks well and is relatively inexpensive.

It may be left plain or lightly toned with polish. It should be fixed with

small brass pins. |

|

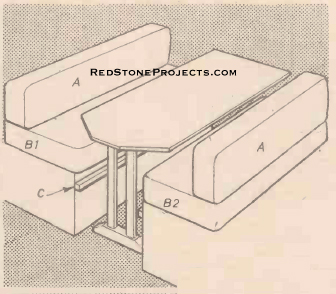

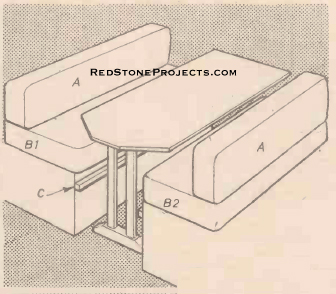

Figure 21. Dinette arrangement. By night table

rests on battens C. B1 lays on table and mattresses. Mattresses A are 12

in. wide. Mattresses B are 23 in. wide.

|

|

| Where fixings cannot be obtained on existing framing,

small 1 in. cubes of softwood can be glued on to the caravan skin at about

6 in. intervals. When cutting the plywood, the use of templates cut from

stout paper is recommended for the awkward shapes.

In small vans it is advisable to keep the interior light

in finish. The roof should be painted dead white, and all interior woodwork

and hardboard should be lacquered in pale tones - birch grey is very pleasant

- perhaps relieved occasionally by some brighter contrast here and there.

Useful ideas can often he obtained by inspecting commercially-built caravans. |

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|