Free Shipping

10 Foot Folding Boat Plans

Build a Portable Boat for Camping, Hunting and Fishing

|

10 Foot Folding Boat Plans

Build a Portable Boat for Camping, Hunting and Fishing

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these vintage 10 Foot Folding

Boat Plans with 12 Pages of Enhanced and Enlarged Figures and

Illustrations and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

| More Vintage

Boat Plans |

|

|

|

|

|

|

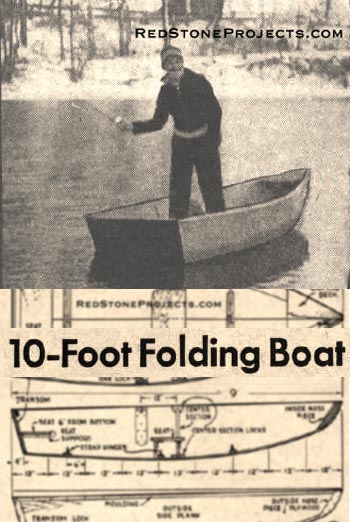

When this fisherman wanted to practice his bait

casting in winter, he folded up his boat, tucked it under his arm, walked

down to the water, unfolded his boat, launched it, and there you are!

|

| Designed as a portable boat for camper, hunter, fisherman,

and outdoor man who wishes a boat for use anywhere but without the bulkiness

of the average rigid one-place craft. It folds to a compact flat bundle

that may be stowed aboard any cruiser, auto, airplane, loaded on a donkey,

or easily carried to point of destination. It is suitable for those hard-to-reach

places where conventional or rigid boats are difficult or impossible to

transport or where boats are not available. Its Super-Harbord marine plywood

construction makes for easy and strong fabrication. |

| Specifications

LENGTH - 10 ft.

BEAM - 41 in.

DEPTH - 15 in. Amidships

WEIGHT COMPLETE - 80 lbs.

SEATING CAPACITY - 3 Passengers

CONSTRUCTION - 3/8 in. Super - Hardboard Marine

Plywood over shaped forms

TYPE - Flat bottom, canvas bound edges |

|

|

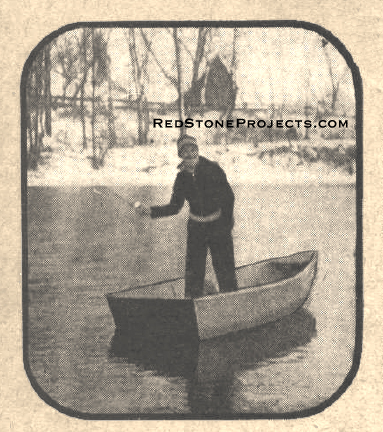

Carrying the folded boat down to the lake. Notice

the folded bottom projecting above the side piece.

|

| Outdoor sportsmen encounter numerous waterways or adverse

conditions where it is impossible to use the ordinary rigid boat, or where

its use is restricted making it more of a liability than a convenience

on a trip. The portable folding boat is not meant to dispense completely

with the rigid boat, but to supplement its uses and to offer a ready means

of water transportation where conventional type boats are excluded.

Weighing only 80 lbs., costing about five to six dollars

for materials, simple and easy to construct, easily rowed or propelled

with small outboard motors from 1 to 5 hp., this portable folding boat

provides a lifetime of usage, under conditions unapproachable by conventional

craft. The hull may be folded or unfolded in one minute's time. It will

stow away inside any auto, airplane, house trailer, or it may be packed

under the arm and carried easily. |

|

Figures

1 and 2. Patterns for sides and bottom with dimensions.

|

Get a restored copy of these vintage 10 Foot Folding

Boat Plans with 12 Pages of Enhanced and Enlarged Figures and

Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

| Another very important service this folding boat can

render is its use as a yacht dinghy on larger boats where the usual dinghy

must be towed or where space is not available. The folding boat is simply

stowed aboard until occasion for its use arises. Many other uses will be

found for this portable boat. Despite its folding, portable properties,

the hull will support three persons and remain stiff and sturdy and seaworthy. |

|

|

Center piece and transom are removed when the

rest of the boat is folded up.

|

| Construction of the portable boat is extremely simple.

Begin by scanning the material list. Collect the various items. Be sure

to use resin-bonded marine plywood for the planking. With the sheets of

3/8 in. marine plywood at hand, transfer the side and bottom plank patterns

as indicated, mark and saw to shape. With one side sawed to shape, use

it as a pattern for the other side. There are two identical side pieces

and two identical bottom pieces. Lay these aside, and saw to shape the

transom, transom seat, center section, seat, and seat support from 3/4

in. marine plywood. |

|

|

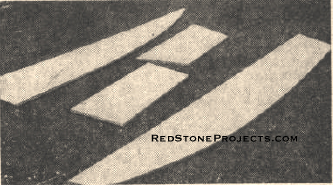

Just a few pieces of marine plywood go into the

making of Handy Andy, the folding boat.

|

| Putting the Bottom Together

The assembly begins by attaching the two bottom pieces

or bottom planks together. Align them side by side, edges touching and

with a strip of canvas two inches wide the full length of bottom pieces;

coat face of plywood where canvas is to be attached with C quality marine

glue. Lay the canvas in position in the exact center of the two bottom

pieces and proceed to secure canvas to bottom pieces each side with 1/4

in. x 3/4 in. lock strips. These strips are to run the full length of the

bottom pieces. Leave a 1/2 in. space between strips and fasten strips to

bottom with screws or clout nails. The easiest and quickest way to fasten

these lock strips in position to all parts of the boat is with 1 in. clout

nails, but lacking these use 3/4 in. No. 6 f.h. screws. Space either nails

or screws about two inches apart. For an ultra-strong job, copper rivets

are best, but either the nails clinched or the screws are quite satisfactory. |

|

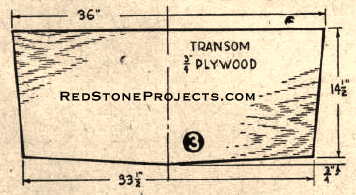

|

Figure 3. Transom with dimensions.

|

| Attaching the Side Planks

With the two bottom pieces locked together the hull side

planks are next attached to the bottom planks. Begin by temporarily assembling

bottom and side plank pieces to transom with a few screws located so they

can be easily removed later and the holes plugged.

Measure for the correct placement of the center section

and fasten this part temporarily to sides and bottoms with a few screws.

Starting aft, bottom and sides are secured with small strap hinges riveted

in place. Use 1/2 in. copper rivets on each side, first drilling lead holes

for them. Measure for these hinges at points indicated upon plans and continue

forward. Before the pairof hinges is installed forward of the center section,

pull the ends of side and bottom planks together with a rope or clamps

and then secure these forward hinges. Allow about 1/8 of an inch clearance

between plank edges when fastening hinges. Fasten the 1/4 in. plywood nose

pieces to inside of side pieces with nails or screws. |

|

Figure

4. Seat and Center Section with dimensions.

|

Get a restored copy of these vintage 10 Foot Folding

Boat Plans with 12 Pages of Enhanced and Enlarged Figures and

Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

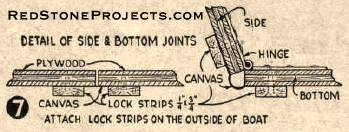

| Starting at the transom, coat edges along sides and bottom

with marine glue. Lay a 2 1/2 in. full-length strip of waterproof canvas

over the side-and-bottom joint allowing some looseness of the cloth for

folding and proceed to fasten two 1/4 in. x 3/4 in. lock strips to canvas

surface alongside and bottom edges. Use clout nails or 3/4 in. No. 6 f.h.

screws, spaced two inches apart. Fasten both sides similarly, working towards

bow and let the lock strips extend over bow to be trimmed later. |

|

|

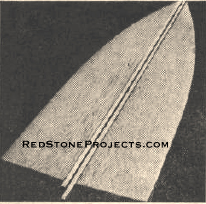

|

The two bottom pieces are joined along the keel

line with a strip of canvas locked in place with two wooden strips. Marine

glue makes it tight.

|

|

| The bow ends of side pieces and bottom pieces are held

together by a piece of waterproof canvas, making literally a canvas bow

stem. This piece of canvas will measure about seven inches wide, to let

it lap over ends of side planks, allowing enough separation between bow

ends for folding. |

|

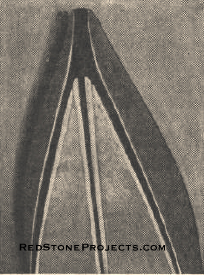

|

Here's the bow end, showing the use of canvas

which serves as hinges for the bottom and sides.

|

| Coat bow ends of side planks with marine glue and place

canvas bow stem in position, lapping over sides and securing with shaped

1/4 in. thick plywood nose pieces screw fastened to side ends. The bottom

of canvas stem piece is slipped under the bottom lock strips and fastened.

Trim the lock strips to fit the nose blocks. |

|

Figure

5. Construction details plan and elevation views with dimensions.

|

Get a restored copy of these vintage 10 Foot Folding

Boat Plans with 12 Pages of Enhanced and Enlarged Figures and

Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

| Now return to the transom and remove the temporary fastenings.

Clamp or rope the sides to hold them securely against transom. Coat sides

and bottom of planking along transom edges with marine glue. Stretch a

piece of the heavy waterproof canvas in place against the transom and lap

over sides and bottom about three inches. Fasten over-lapped canvas to

side and bottom planks with 1/4 in. x 2 in. plywood strips nailed or screwed

in position. This canvas outer transom is not fastened at any point to

the 3/4 in. plywood transom, as the plywood transom is removed when the

boat is folded. |

|

|

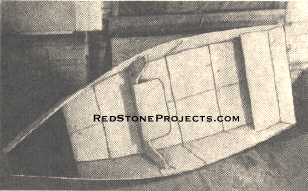

The completed boat with canvas “deck” stretched

across the bow. Removable center section with seat, plywood transom, and

transom seat hold the boat rigid when it is opened up. The parts named

can be taken out and installed quickly.

|

| The 3/4 in. plywood transom is held securely in place

and reinforced especially where outboard motors are used by the installation

of small T-shaped hinges, one to each side (long end of hinge screw fastened

to transom and the short ends held securely to sides of hull with 1/2 in.

x 1 in. r.h. stove bolts and wing nuts). These bolts are removed when the

hull is folded. The 3 in. thick plywood transom fits into two rests which

are simply 3/8 in. shaped and notched plywood pieces screw-fastened to

sides of hull with 3/4 in. No. 6 f.h. screws, place these notched seat

rests so the transom will be held securely against the transom canvas with

enough tension to prevent loosening. |

|

|

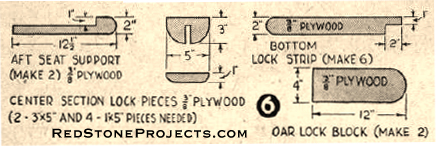

Figure 6. Center Section Lock Pieces with dimensions.

|

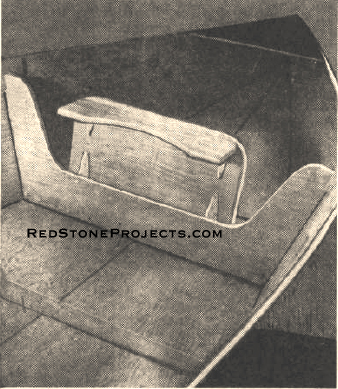

| Finishing Details

The center seat is now attached to the center section

with strap hinges as indicated and the seat support is similarly hinged.

This allows the entire assembly - section, seat, and seat support - to

fold compactly together. The center section is held securely in place with

a notched lock piece of 3/8 in. plywood as indicated. This piece is fastened

to sides with 3/4 in. No. 6 f.h. screws. |

|

|

Figure 7. Details of Side and Bottom Joints.

|

| Notched bottom locks secure the edges of the two halves

of bottom together and are fastened to bottom with 3/4 in. No. 6 f.h. screws

at points indicated.

At the point where side-mounted oar locks are to be installed,

3/8 in. x 5 in. plywood oar blocks are fastened to sides of hull with 3/4

in. No. 6 f.h. screws. |

|

|

Canvas encloses the transom end of the boat. It

is stretched tight when the plywood transom and transom seat are in place.

|

| The sheer molding consists merely of two Pieces, 1/4

in. x 3/4 in. strips, which are nailed or screw-fastened to sheer edges,

screws spaced about four inches apart. Before fastening the bow ends of

moldings in place stretch a piece of the heavy waterproof canvas in place

for the deck and then secure this along edges with the well-fastened moldings.

Mount the oar locks. |

|

The hinged seat folds up and is removed with the

center

section, which is locked in place when the boat is

in use.

|

| Handy Andy is now ready for finishing This should be

a priming coat of equal parts linseed oil and turpentine, followed by three

coats of spar varnish inside and out.

To fold the hull, simply lift transom and seat out first,

then the center section and seat, and press the bottom inward - and the

job's done. Provide a web strap for holding the folded hull closely together

when carrying it. |

|

|

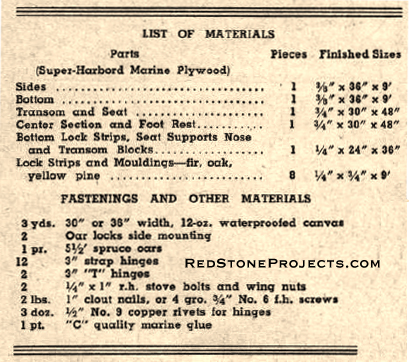

Handy Andy Folding Boat List of Materials

|

|