Free Shipping on All U.S. Orders

All Orders Processed on a Secure Server

Cruisemite Deluxe Travel Trailer Plans

Build a Vintage Steel Frame Camping Trailer

|

Deluxe Travel Trailer Plans

Build a Vintage Steel Frame Camping Trailer

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these vintage Cruisemite Deluxe

Travel Trailer Plans with 16 Pages of Enhanced and Enlarged Figures

and Illustrations and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

|More

Vintage Trailer Plans|

|

|

|

|

|

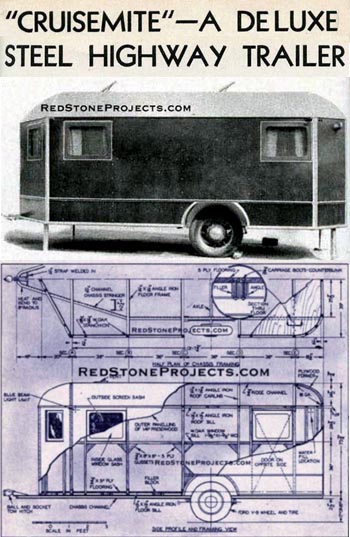

"CRUISEMITE" - A DELUXE STEEL HIGHWAY TRAILER

Designed for the person whose income is limited, this

camping coach is unique. It is of all-steel construction, yet cost no more

than inferior types.

|

|

|

|

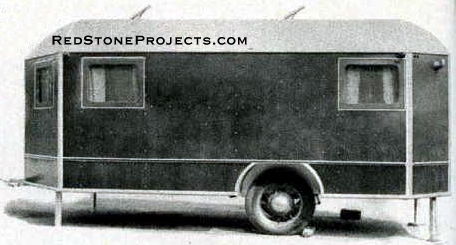

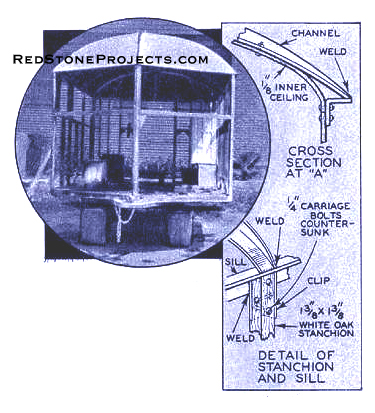

Completed Cruisemite, featuring conveniences found

only in expensive travel trailers.

|

| THE trailer Industry, having grown by leaps and bounds

during the past few years, it is difficult to determine just which type

to build. While there are streamline trailers, folding trailers, long trailers,

semi-trailers and any number of in between types, "Cruisemite" is a practical

coach for home construction. It has been seasoned by thorough testing and

free from undesirable features.

"Cruisemite" may be built in several ways with any number

of interior plans. That's half the fun of building a trailer: Planning

the interior yourself. A good standard layout is shown in the plans.

The secret of the easy-to-build part of "Cruisemite" is

that she has a steel chassis roof frame. This is welded up out of standard

steel channels and angles obtainable at any building supply dealer. A blacksmith

can be called upon to bend up the materials and weld the frames.

Being of steel, "Cruisemite" construction Is very strong,

as well as being very light. |

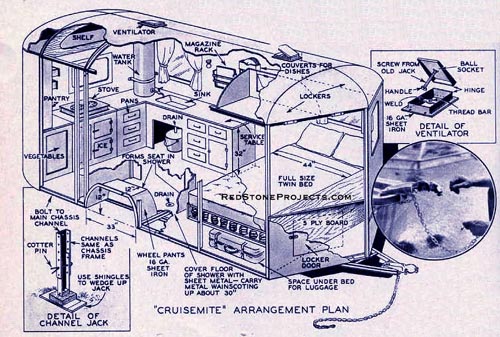

Cruisemite Arrangement Plan

On the original Cruisemite, this form of trailer hitch

was used. Being of the ball and socket type, the trailer hauled smoothly

without the effects of slack jarring it into motion.

|

|

| The main chassis frame is of channel iron of 2 1/2" deep

as shown on the perspective drawing. Lay out the half-breadth dimensions

and chassis frame lengths in chalk on the cement floor of the garage. Have

the channel bent in the middle and at section B to coincide with the floor

plan. |

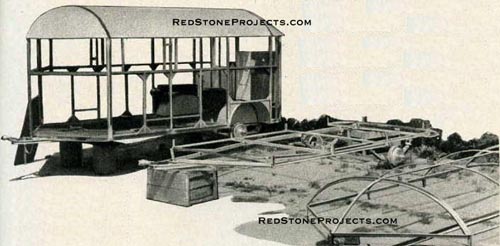

Here is the trailer as it appears before the ceiling

process has been started.

Note the roof in place.

|

|

| The bend in the middle is to a radius of 8", making a

sixteen-inch loop into which the trailer hitch is later fastened. |

|

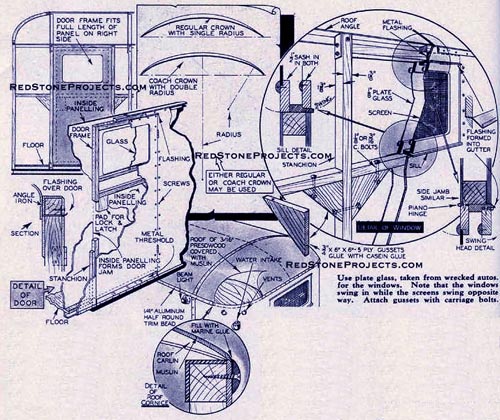

All dimensions required for constructing the roof and

floor framework are given in the above diagram. Channel and angle iron

welded to the required forms constitute the chassis.

|

Get a restored copy of these vintage Cruisemite Deluxe

Travel Trailer Plans with 16 Pages of Enhanced and Enlarged Figures

and Illustrations and Searchable Text.

|

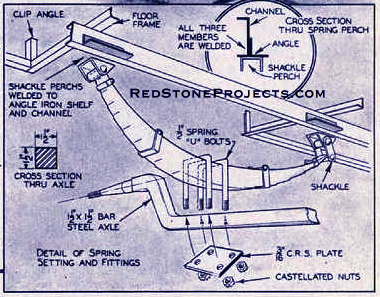

| Lay the main chassis frame on the floor, and using the

chalk outlines as a guide, weld in the cross members, the outside edge

angle iron as shown on the drawings and also the clips. These clips are

of the same material. 1 3/8" by 1 3/8" angle iron and about 4" long. When

this work has been completed, turn the frame upside down and weld in the

angle irons and the plates for the spring perches.

The spring used is a 28" Chevrolet truck type with 4"

shackles to allow a soft riding motion. Install these as shown then install

the axle and the wheels. |

|

Details of The Chassis Framing are clearly shown here.

The builder is cautioned not to alter the basic design of the craft except

for the stanchions which can be altered to provide the necessary headroom.

Pants of galvanized iron are attached over the wheels to improve the trailer’s

appearance. A commercial pressed wood material is used for side construction.

|

Get a restored copy of these vintage Cruisemite Deluxe

Travel Trailer Plans with 16 Pages of Enhanced and Enlarged Figures

and Illustrations and Searchable Text.

|

| It is suggested that you use a manufactured axle as this

will have the ends machined for the spindle, and upset. However, any blacksmith

can make you a steel axle with spindle ends for a pair of Ford V-8 front

wheels and upset them for the spring depth. The axle must be upset as the

bar must pass under the spring. This is not only good mechanical sense,

but in many states, it is law.

Make the standing jacks, as shown in the detail, next

so that the wheels can be fastened on the spindle, packed with grease,

and permanently installed. The frame completed, construction is started

on the roof. The frame for the roof is built as shown in the perspective

detail drawing. The roof beams are tapered on the top edge, either by weld-cutting

and grinding smooth, or hot shearing so that at a foot from either side

of the center line they taper to nothing at the ends. They can be bent

to an absolute crown of 14" or a coach crown whichever is desired. Weld

the beams, saw out for the 3/4" center or ridge pole channel and weld in

the stanchion clips. |

|

|

|

Method of attaching the springs to the trailer

chassis.

|

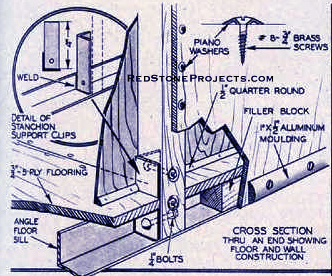

| You will need 20 (twenty) 1 3/8" by 1 3/8" white oak

pieces planed four sides and finished to a maximum of 6" more or 4" Into

than 5 1/4", depending upon the height desired.

At this stage of construction procure about four or five

small C clamps and with the help of a few friends fasten the stanchions

at sections A and E of the chassis frame which has been jacked up level.

Install with 1/4" bolts, countersunk as shown, two transversely and one

plain longitudinally. You can bore through the clips easier if an electric

drill is used. Plumb the stanchions before final bolting, and then get

your friendly help to assist in hoisting the roof truss. This will set

on the erected stanchions. It also must be faired and bolted using the

C clamps to secure it while the bolting process goes on.

Now install the other stanchions. Put in those with the

clips, top and bottom, first. The extra, unclipped ones are for the window

frames and are attached with single bolts transversely into the longitudinal

face of the angle irons. At this stage of the game, you will find your

trailer in the same condition as a house frame with all the studding and

plates installed. |

|

|

The original Cruisemite chassis is pictured here

with the roof and floor of a second one. The entire framework is welded

together to form a rigid chassis.

|

| Mount the middle body panel sills at the top and bottom

of the windows. These are exactly 4' from the top of the main chassis channel

to the top of the sills. The ends butt flush to the stanchions, and are

not let in. Plywood gusset plates are fastened with casein glue and bolt

to both the stanchions and the sills, with the outer faces coming flush

to the outside of the frame members to give backing to the paneling.

At this point the outer roof ceiling can be fastened on.

It is made of 3/16†pressed wood sheet, cut in convenient

panels and bolted with 1/8" machine screws into the ridge and channel members.

There will have to be occasional filler blocks placed in the angles for

the wood to bear against. Under the forward crown of the ridge pole or

center channel you will cut a 1/2" by 1 1/4" plywood carlin or former into

which you can later fasten the inner ceiling at this point. The curved

formers at the rear of the roof are. as the drawing shows, 3/4" by 1 3/4"

carlins. These are fastened to the channel with 16 or 14-gauge clips, and

bolted through. Use screws on the wooden members to fasten the pressed

wood down, starting at the center ridge, and working the panels down to

the edge.

After the outer portion of the roof is attached, wire

up the trailer for lights. There should be three circuits: one for 110

volts for use in parks and in the rear of your home, where you may want

to use the trailer as a spare bedroom. There should also be a set of wires

for the smaller voltage lights which can be run from the car battery upon

occasion, or from an independent generator set. The third set of wires

connects directly from car to running lights, which consist of a red tail

light with license plate, brake light, required by law in most states,

and the blue beam limit lights which insurance companies require if you

are to have coverage, and which in most states is required by law.

Plan the light outlets to suit the layout you have chosen.

About four 110-volt lights, and 6 to 12-volt outlets are sufficient. All

of the leads can be carried from the car to the trailer through a rubber

covered cable about 1/2" diameter, with five or six colored wires im-bedded;

enough to carry whatever circuit you want.

Since no car battery can stand the strain of more than

one overnight operation of trailer lighting requirements, a small A. C.

generator, powered by the car's motor should be used.

The pants for the wheels must be so fashioned that they

will have about 1" clearance over the wheels when the spring is fully depressed. |

|

|

Manner in which the floor and stanchions are mounted.

|

| A good form for dimensions is given in detail. They can

be made up by any tinsmith out of 16 to 14-gauge metal, with rivets and

soldered seam and bent up flanges for fastening.

The trailer floor is built of 5-ply 3/4" fir panels bolted

through the filler blocks laid in the channel irons, with the heads counter-sunk

as shown in the detail plans. The clips are set in by rough saw cuts as

this portion of the floor is covered later by the ceiling.

Screw 1" half round between the stanchions with its bearing

face flush to the inside face of the stanchions. This will afford a hold

for the inner ceiling, which may be of 1/8" or 3/16" fir plywood, or pressed

wood.

Painting the framework is next. Use boiled linseed all

and turpentine, mixed half and half and kept in a double boiler to heat

it. Apply a coat of the mixture to all the outside wooden members and steel

work. Apply several coats to the wood to prevent dry rot.

Before putting on the outside ceiling, cover the roof

with grade A muslin, and dope it with airplane dope, after which the roof

is sprinkled with aluminum powder. |

|

|

The door, like the rest of the side construction,

is built of pressed wood. The door frame is located on the right side of

the trailer and fits the entire length of he panel. Stanchions serve as

a frame for the door.

|

| The dope will hold the muslin to the ceiling although

a few tacks will be needed at the edges to temporarily hold the muslin

in place. Dope a few coats along the outer edges first, allowing a good

three to four hours in the sun for drying, then do the balance of the roof.

Now for the outside ceiling, which completes the work.

The water tanks and the piping for the shower have been put in, and you

are ready to finish up the job. This is merely a matter of doping the right

size panels to cover the frame, laying it on with good thick casein glue,

which holds like grim death, and prevents body squeaks. Use No. 8 3/4"

chromium head screws set in piano washers for this, spacing about centers

about 9". The seams of the panels should be joined on a jointer, and not

left rough as they come from the saw. It would be well to fill the seam

with casein as the panels go on, wiping off the outer edges immediately

with a damp rag.

On the bottom and at the seam where the roof meets the

side, put 1/2" oval aluminum stripping. At the roof, there will be an out

gage caused by the crown. Fill this with Jeffery's C quality marine glue,

applying hot from a squirt can. The can will pay out enough to make a full

seam. Keep a can of turpentine and a rag handy to enable you to avoid sticking

up the job. Marine glue must be put on hot, and all slop-overs wiped off

immediately. The heating can be done in a pot of boiling water. Keep the

glue away from all flames. A bead of glue should also be run around the

edges of the ventilators.

A few coats of good spar varnish are applied both inside

and out as there is nothing as weather resistant.

The skirt molding is put on, and the trailer is finished

except for the interior joiner work such as drawers and closet doors.

The hitch is a good ball and socket type. There are many

ways of installing these, but it has been proved best to do it, using both

welded joints, for rigidity, and bolts for security. You cannot afford

to have a failure occur here. The ball end and the details of this part

of the hitch must be taken from the car itself. Fasten the ball hitch to

the car frame, and NOT TO THE BUMPER. |

|

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|