| Although we used a 2-stroke cycle Clinton A400 engine,

almost any 2 or 4 stroke cycle having a maximum 2 1/2 hp could be used.

The lightweight, vertical cylinder, horizontal shaft, 4 cycle engines,

such as the Clinton A2100 or Briggs and Stratton 6B or 6B-5, offer some

advantages over the 2 cycles in that they can be throttled down to run

smoothly at slow speeds, are easier to start and do not require mixing

of oil with the gas Do not, however, use any of the heavy cast iron engines

since their additional weight located off center on this small powercycle

tend to make steering difficult and erratic.

For complete construction details of cycle and side cart,

see the blueprints included.

|

|

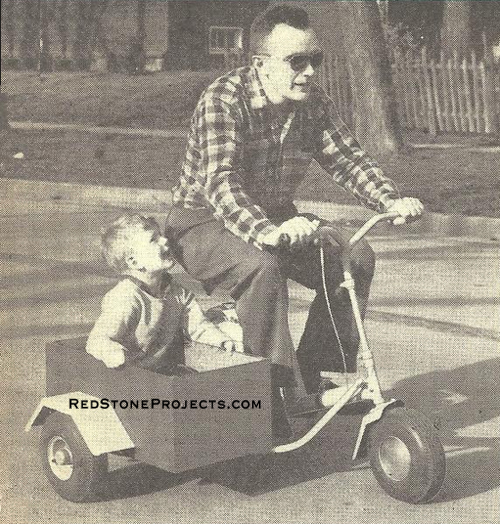

Although the side cart is not intended for a passenger,

the Editor couldn't resist giving a local admirer a cautious ride.

|

|

| You'll have transportation for yourself (Fig. 1) plus

load carrying capacity with this little side-cart equipped powercycle.

And the cart (Fig. 2) can be detached in the time it takes you to loosen

three bolts.

Since the shape and size of the frame members must be

determined by the size of other matching parts, have all of the parts given

in the Materials List on hand before starting actual construction. |

|

|

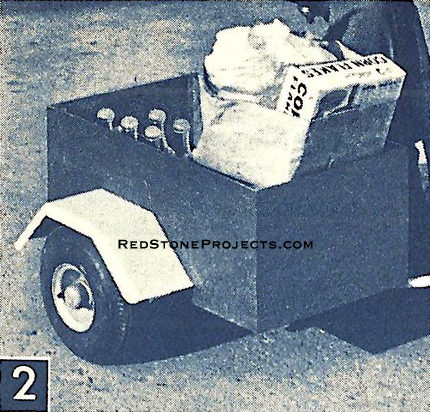

Figure 2. PowerCylce Detachable Side Cart

|

| Making the Cycle Frame

Begin by hacksawing the Chevrolet propellor shaft to length

as given in Fig. 5A. Chuck, or tack weld a block on the tube end of the

shaft for a center, and mount the prop shaft in a metal-turning lathe.

The lathe will have to have a 3-ft, between-centers capacity.

If you do not have a lathe to do this work yourself, it

will pay you to have the front fork (Fig. 5B) ready for machining too,

so that you can have all of the lathe work needed to build this cycle done

at one time.

|

Get a restored copy of these vintage Mini Bike Plans

with 19 Pages of Enhanced and Enlarged Figures and Illustrations

and Searchable Text.

All Orders Processed

On a Secure Server

|

Figure

3. Side Cart Assembly

|

The front fork is made from a Mercury sway bar which

is heat-treated spring steel and may be a little too hard for sawing and

machining without first annealing. To anneal the bar, heat it to a dull

red and allow it to cool slowly. You can do this with an acetylene torch

or, better still, if there is an automobile spring shop or heat-treating

firm in your area, have them heat the entire bar in their furnace. |

|

|

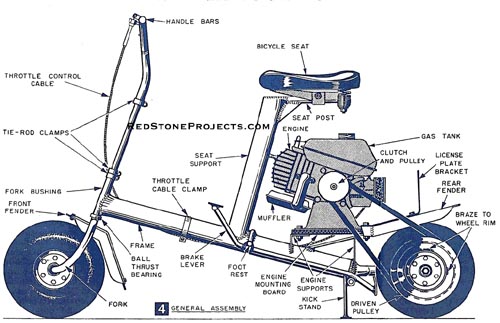

Figure 4. General Assembly

|

| After machining the front and rear axles, assemble the

wheels on them to make certain everything fits well. Then lay out and cut

the two bending templates from sheet metal as in Fig. 5. When bending the

rear axle and front fork, grip the stock in a vise and use an acetylene

torch to heat just those areas of the stock that you are bending. Heat

to a bright red and do not hold the torch too long or too close at one

spot. If the metal starts to sparkle it indicates it is burning and is

too hot. Do not quench with water to cool but allow to cool slowly to room

temperature. |

Get a restored copy of these vintage Mini Bike Plans

with 19 Pages of Enhanced and Enlarged Figures and Illustrations

and Searchable Text.

All Orders Processed

On a Secure Server

|

Figure

5. (1 of 9) Frame Assembly

|

An 18-in. length of 1/2-in. black iron pipe with one

end drilled out to 5/8-in. so that it can be slipped over the ends turned

down for the axles, will protect the machined surfaces, and give you the

leverage needed for bending. Use the bending templates to check the amount

and angle of the bends occasionally. Final accuracy of bend must be checked

by mounting the wheels with tires. Wheel centers must be in line with centerlines

of shafts and have clearance for tires. Allow space for installation of

fender on front fork. Note that the front fork has a secondary bend, other

than those shown on the template, of 2-in. forward for wheel caster effect.

The rear axle arm is bent 15° from centerline of tube as in frame assembly

drawing Fig. 5.

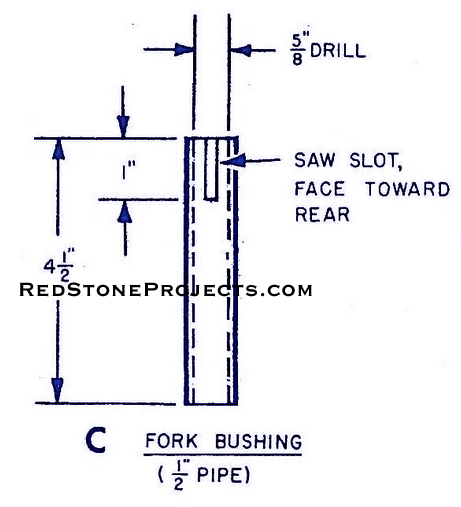

Cut the fork bushing (Fig. 5C) from 1/2-in. pipe and run

a 5/8-in. drill through it to clean up the inside so that the bushing will

slide on the turned portion of the front fork. |

|

|

Figure 5. (2 of 9) Front Fork

|

|

| Then flatten the end of the frame tube (A), and file

the top and bottom edges of the tube half round to take the fork bushing

at 85% as in the frame assembly drawing Fig. 5. After welding the bushing

to the frame, again drill it out because the heat of welding may have distorted

it somewhat.

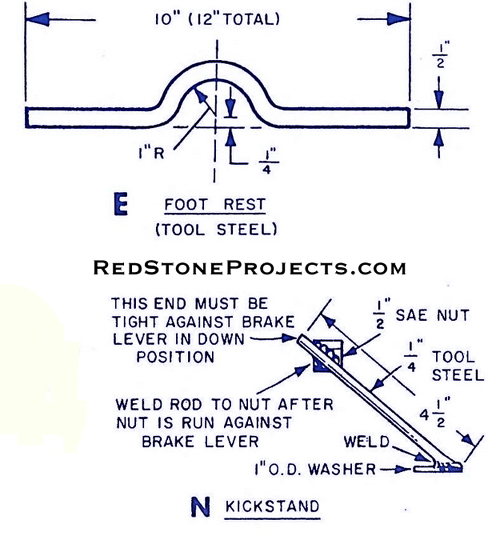

Use the cut off piece of prop shaft tubing for the seat

support (Fig. 5D). Grind or file the end of the support to fit tightly

against the frame tube. This operation, which is commonly called "fish-mouthing"

the end of a tube, will make welding a lot easier because you will not

have gaps to fill. If you are going to use a Clinton engine as we did,

weld the seat support to frame A, locating its center 12-in. from the rear

end of the frame tube as in the frame assembly Fig. 5. If you are going

to a Briggs and Stratton aluminum vertical cylinder engine, locate the

seat support 10-in. from the rear end of the frame tube. Then heat and

bend the foot rest (E in Fig. 5), and weld it to the frame tube right in

back of the seat support. |

|

|

Figure 5. (3 of 9) Bending Templates

|

|

| To determine the angle at which the remaining parts are

welded to the frame, temporarily assemble the front and rear wheels on

their axles. Then slide the ball thrust bearing on the front fork and insert

the fork through the fork bushing on the frame. Place one tie-rod clamp

at the top of the fork bushing over the saw slot and another clamp above

it on front fork shaft (Fig. 4) to keep it from sliding out of the bushing.

To support the cycle and keep it in an upright position

while you work on it, make up a wooden stand from scrap 1 x 4-in. stock

as in Fig. 3A. Place the stand under the foot rest, and weld the seat post

to the top of the seat support so that it is parallel with the floor. Hacksaw

the gusset from a piece of 1/8 x 1-in. strip steel and weld it to the corner

where the seat post joins the seat support as in the frame assembly Fig.

5. If you are using the vertical cylinder engine with the seat support

located closer to the rear, you will not need the gusset and can make the

seat post only 5 in. long.

Engine Installation.

While you are at the auto wrecking yards have the yard

man cut you the two engine supports (Fig. 5F) with an acetylene torch.

To save time at the yards, make up paper patterns of the engine supports

and have them ready so that you can place them on an old car frame channel

and draw around them with chalk. Have the yard man cut off car 2 x 2 1/2-in.

piece of 1/8-in. thick steel for the brake too. Grind the rough-cut edges

of the engine supports smooth and weld them to the frame as in Figs. 4

and 5F. Reinforce the rear engine support with 1/4-in. steel rods welded

in place. |

|

|

Figure 5. (4 of 9) Engine Supports

|

| The best V-belt pulley to use for the rear wheel is a

7-in. diameter water pump pulley from a Chevy, Olds, or Buick because it

has an offset center which provides clearance for the tire. Cut out the

center of the pulley and braze it to the rim of the rear wheel at four

places as in Fig. 4. Then reassemble the wheel and mount it on the rear

axle with slotted nut and cotter pin.

Now, with a V-Plex automatic clutch on the engine drive

shaft, place the plywood and engine on the engine supports as in Fig. 4.

Line up the V-belt pulley on the engine with the one on the rear wheel

and measure the size V-belt needed. After purchasing the belt, place it

on the pulleys and mark the location of the engine mounting holes on the

engine supports. Drill these holes 3/8-in. and bolt the engine in place.

To take up belt stretch later, a piece of plywood 1/4 to 3/4-in. thick

may be placed under the engine base as in Fig. 4. |

|

|

Figure 5. (5 of 9) Fork Bushings

|

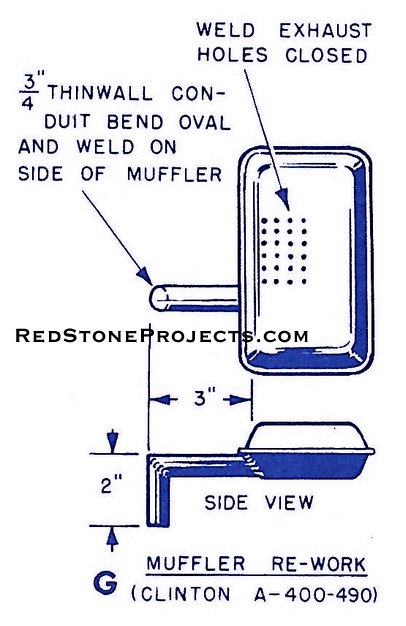

| The performance of the Clinton A400 engine can be improved

by opening up the baffle plates inside the muffler (G in Fig. 7). Weld

the exhaust holes closed and for a new exhaust opening, weld a 3-in. length

of 3/4-in. conduit to the muffler. If you are going to use the side car

on the cycle, weld another 3-in. length of conduit to the exhaust opening

as in the side view Fig 7 to direct the hot gases away from the side of

the car.

Handle Bars

Make the handle bar from a '48 Ford tie rod, bending and

welding them as in Fig. 5H. Weld a 3/8 x 2 1/2-in. cap screw to the right-hand

side of the handle bar for mounting the throttle control handle made from

3/4-in. conduit as in Fig. 5H. Weld the throttle-cable support to the underside

of the handle bar and slide the cable through it. Thread or spot braze

the end of the cable to the supporting 3/8-in. nut. The wire inside the

control cable is fastened to the swivel clamp bolted to the conduit handle.

Run the cable back along the cycle frame and connect it to the carburetor

throttle lever. Disconnect and remove the engine governor linkage, and

change the lever (J in Fig. 7).

|

|

|

Figure 5. (6 of 9) Brake Lever

|

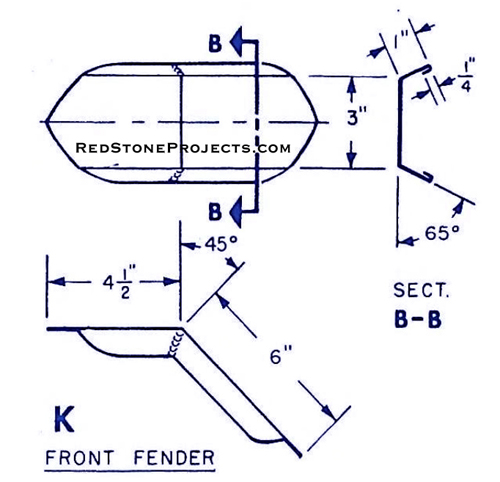

| Fenders

Fenders are required by law in some states for licensed

scooters. We made ours from pieces of car body sheet metal which is soft

and can be easily cut and bent to the shapes shown in Fig. 6.

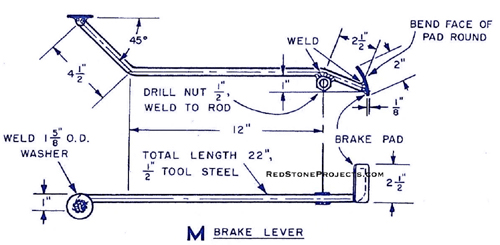

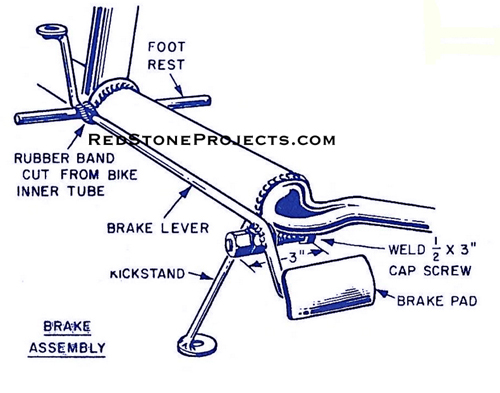

Brake

Be sure to use 1/2-in. round, water hardening tool steel

for the brake lever because ordinary cold-rolled mild steel may bend out

of shape and leave you without brakes. Make the brake as detailed in Fig.

5M and mount it on a 1/2 x 3-in. cap screw welded to underside of the frame

as in brake assembly Fig. 5. Drill the threads out of the 1/2-in. hex nut

welded to the foot brake so that the nut will slide on the cap screw. Then

run a 1/2-in. hex nut on the cap screw to retain the brake lever. This

same nut is used for the kick stand too. Be sure the nut is on the cap

screw before welding the kick stand (Fig. 5N) to it because it would be

impossible to install the kickstand otherwise. The nut must also have enough

thread drag or friction to hold the kick stand in the up position. If the

nut is too loose, collapse it slightly by squeezing in a vise before installing

it.

|

Get a restored copy of these vintage Mini Bike Plans

with 19 Pages of Enhanced and Enlarged Figures and Illustrations

and Searchable Text.

All Orders Processed

On a Secure Server

|

Figure

5. (7 of 9) Handle Bars

|

| With the exception of lights and a horn, required by

some states before you can get a scooter license, your power cycle should

be complete and ready for a test run. The horn can be the rubber bulb,

beep-beeb type available at auto parts and dime stores. The lights (head

light and tail light) can be operated by a dry cell battery or the type

used for bicycles. |

|

|

Figure 5. (8 of 9) Brake Assembly

|

| Side Cart

The best procedure to follow in making and assembling

the side cart to the power cycle you have built is to cut and fit the four

cart frame pieces (Fig. 3) individually. Start by making the axle extension

from a 20 1/2-in. length of 1/2-in iron pipe. Weld a 5/8 x 2 1/2-in. cap

screw on one end, and heat and flatten the other end. Make up three cart

attachment lugs as in Fig. 3B and bolt one to the flattened end of the

axle extension. Then, with the wheel mounted on the axle extension and

the cycle blocked in the upright position on the floor, place the lug end

of the axle extension against the rear axle arm of the cycle as in Fig.

3. Cut a couple of 2 x 2-in. blocks for holding the axle extension level

with the floor and at right angles to the cycle frame. If you are doing

your own welding, tack weld the lug to the rear axle arm of the cycle.

Otherwise, clamp or wire the lug to the arm. |

|

|

Figure 5. (9 of 9) Foot Rest and Kick Stand

|

| ***Caution***

Welding near a gasoline tank can be dangerous business.

Be sure to drain gasoline from engine gas tank and carburetor and blow

out tank before welding. Or better still, remove the engine from the cycle.

Next, make cart frame part X in Fig. 3. Bend and fit

the end that is fastened to the axle extension first. Then bend, cut and

flatten the end to be attached to the cycle frame with a lug as in Fig.

3C. Use blocks to hold part X level with the floor and tack weld or temporarily

wire the lug to the cycle frame.

Now cut and fit part Y in position, tack welding or taping

it with plastic electrician's tape to hold it in place. Follow by fitting

part Z in place, fastening the end to the cycle seat support with a lug.

Cut the triangular shaped pieces, which reinforce the cart frame and provide

mounting-bolt holes for the cart box, and weld them to the frame members.

Also complete all the other welding of the lugs and cart frame joints while

it is still attached to the cycle to avoid distortion of the parts due

to heat of welding. |

|

|

Figure 6. (1 of 2) Front Fender

|

|

|

Figure 6. (2 of 2) Rear Fender

|

| The cart box is made of 1/4-in. exterior plywood reinforced

with cleats at all inside corners as detailed in Fig 3D. Bolt it to the

frame with three 1/4-in. fh bolts. Make the cart fender (Fig. 6) from sheet

metal as you did the cycle fenders, and bolt it to the cart box. Use shakeproof

nuts on the three bolts that fasten the side cart to the cycle so there

is no danger of the nuts vibrating loose. |

|

|

Figure 7. (1 of 2) Throttle Rework

|

|

|

Figure 7. (2 of 2) Muffler Rework

|

|