Free Shipping

Truck Camper Plans

Build a Simple and Rugged Pick-Up Based Weekend Retreat

|

Truck Camper Plans

Build a Simple and Rugged Pick-Up Based Weekend Retreat

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these vintage Pick-A-Back

Truck Camper Plans with 13 Pages of Enhanced and Enlarged Figures

and Illustrations and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

|More

Vintage Trailer Plans|

|

|

|

|

| DESIGNED expressly for the owner of a small pick-up truck

who likes to get in all the fishing or hunting possible over a weekend,

this pickaback house trailer is "ready to go" on a moment's notice. As

soon as you're through for the day, slip the trailer into the truck bed,

and you're all set to head for that favorite lake or trout stream. The

trailer includes all the accessories necessary for real comfort, such as

storage lockers for food and clothing, gas stove and supply tank, toilet

and bed.

Dimensions of the center section allow 66 in. of headroom.

Of course, by simply lengthening the frame uprights it is possible to increase

the headroom to 72 in. or more, but the proportions of length and width

to height would lack the symmetry of the original design. Also, any increase

in the over-all height would make the unit less adaptable to travel on

narrow roads or trails in the back country. |

| You get a good idea of the construction from the cutaway

view in Fig. 1. Note that the walls and ceiling are of approved trailer-type

construction with a blanket-type insulation between inner and outer wall

coverings. Note also how the floor is offset at the sides to form a ledge,

or seat, at each side of the center section. Because of variations in the

size of the bed on various makes of pick-up trucks, some of the dimensions

given in the details may have to be altered to fit the truck bed. Be sure

to take careful measurements of the width, length and the height of the

sides of your truck bed before cutting any materials. When finished, the

body frame should slide easily in and out of the truck bed without binding

at any point.

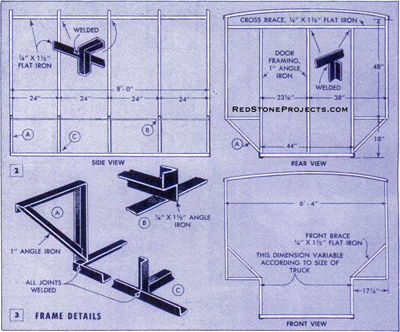

The frame is made of welded angle iron and consists of

five vertical members joined across the top by carlins, or rafters, curved

to a 3-in. crown. Spaced on 24-in. centers, the five frames give an over-all

length of just over 8 ft. As you will see from study of the details and

the accompanying photos, the frames are joined longitudinally at the bottom

corners by 1 1/2-in. angle-iron rails, detail C in Fig. 2, which serve

as stiffeners and also as sills, or runners, for sliding the unit on and

off the truck bed. At the upper corners, 1/4 x 1 1/2-in flat-iron strips

are butt-welded to the frames, upper left-hand detail in Fig.1. Note that

each frame is welded as a separate unit before welding on the bottom rails

and the flat-iron strips, or plates. In welding the frames, the bottom

U-shaped member is made by bending A-frames from angle iron, V-notching

one leg at the point where the bend will come. Then, after bending, the

meeting edges are welded. |

|

Figure

1. Body Assembly

|

Get a restored copy of these vintage Pick-A-Back Truck

Camper Plans with 13 Pages of Enhanced and Enlarged Figures and

Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

| The A-frames are welded to the bottom cross rails and

the uprights are butt-welded to the outer ends. Then the curved carlin,

or rafter, is welded in place to finish the individual frame. Care must

be taken in welding to get frames of a uniform size. Use of a welding jig

will assure uniformity. If the builder is not an experienced welder, it

will pay to have all welding done by a professional. |

|

|

Figures 2 and 3. Frame Details.

|

| Now, note that a flat-iron strip is welded to the A-frames

under the over-hang on both sides, detail B in Fig. 2. These strips run

the full length of the body frame and serve the dual purpose of making

the frame more rigid and at the same time providing a convenient rack for

lashing a tent, tarpaulin or other extra equipment for some special purpose. |

|

|

Novel step-seat folds inside to form a comfortable

seat, making use of all available space.

|

|

| Two extra uprights and one full-width horizontal member

make the door frame as shown in Figs. 1 and 2. The uprights are 1-in. angle

iron and the cross member is of flat iron, as indicated in the rear view,

Fig. 2. Also, two diagonal angle-iron braces are welded across the A-members

of the back frame, detail A in Figs. 1 and 2. |

|

|

Underneath view of body offset and the angle iron

framing which fits inside the bed of the truck.

|

| Note especially that the same braces at the front of

the frame are placed above the overhang as in the front view, Fig. 3, and

that flat iron is used instead of angle. It is necessary that the front

braces be placed in this position to prevent interference when loading

the body onto the truck bed. |

|

|

The angle-iron frame of the "Pick-A-Back" trailer

body with the floor and front pane installed. Note the front window opening.

|

| After all metal parts of the frame have been welded together

to form a unit, the next step is to install the tongue-and-groove flooring.

Lay the center section first, and then carry the flooring up the vertical

sides and across the overhang on each side as in Fig. 1. Because of the

metal "joists" the flooring must be attached with 1 1/4-in. 8-32 machine

screws with nuts and lock washers. The clearance holes for the screws are

drilled through each flooring board and through the angle iron. Use one

screw at each frame, drilling through the center of the board. Be sure

that the boards are drawn tightly together as they are laid. It's a good

idea to shellac the boards before laying to prevent absorption of moisture. |

|

|

Loading the unit is easy by supporting the front

end on sawhorses.

|

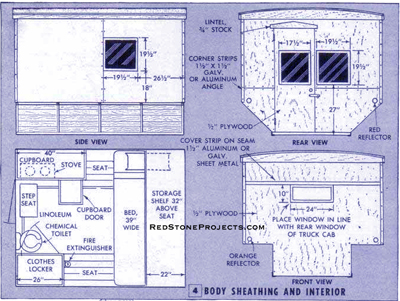

| Next, install the front and back panels, Fig. 4. These

are cut from 1/2-in. waterproof plywood and are attached to the angle-iron

framing with machine screws of the same size as used for the flooring.

After installing the front and back panels, measure and cut an opening

for the front window. This is centered in the body frame and is at the

same height as the rear window in the truck cab. Note also the position

of the rear windows, one in the door and the other in the body panel, rear

view in Fig. 4. These three are unit sash and are not adjustable. Placing

the sash in this position enables the driver to see the road through the

rear-view mirror in the truck cab. However, as an added precaution it's

a good idea to install a truck-type extension mirror on the cab. |

|

|

Roof carlins, or rafters, are formed to form a watershed.

Rafters are faced with wood strips.

|

| At this stage, the body frame can be loaded onto the

truck for completion of the job. The first thing is to attach wooden strips

to the angle-iron frame members at the sides and across the roof carlins

so that the outer and inner wall panels can be screwed in place. |

|

|

Figure 4. Body Sheathing and Interior.

|

| Note the lower center detail in Fig. 1, which shows how

a wide wooden strip is attached to the center frame to back up the joint

in the inner wall covering. All the other strips are attached to the front

side of the frame members. Either wood screws or machine screws with nuts

can be used to attach the wooden strips to the angle-iron uprights. The

wooden roof strips are centered over the curved carlins. |

|

|

Figure 5. Window Detail

|

| Next, attach the side panels which are cut from 1/4-in.

tempered hardboard. The joint on both sides is made over the center upright

as in the side view, Fig. 4. It should be set in waterproof glue and fastened

with two rows of screws which are equally spaced 4 to 6 in. apart. Now,

attach the trim strips, or nailing strips, across the front and back and

the sides as in the side, rear and front views in Fig. 4. Note that the

front and back strips are band sawed to the curve of the roof carlins.

The top edges of the side pieces are beveled to meet the curve of the carlins

to get a smooth, tight joint between the sides and the roof covering.

The top panels also are of 1/4-in. tempered hardboard

and are joined on the center carlin. Use waterproof glue in all the joints

and fasten with flatheaded wood screws equally spaced in straight rows.

Allow the top panels to project 1/16 to 1/8 in. all around to allow for

inequalities in fitting. The projections are planed flush after the roof

is finished. Finally, the four aluminum angles are attached. These protect

the corners of the body and help to prevent leaks. |

|

|

Kitchen stove, pantry and drop-down counter.

|

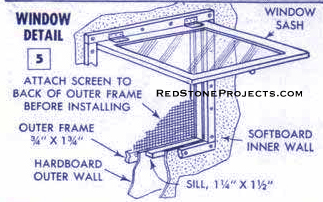

| Next, cut openings for the side windows, Figs. 4 and

5, and you're ready to finish the interior. Nail in 3/4 x 1 1/4-in. strips

to form sills as in Fig. 1, then apply insulating material to the walls

and ceilings. Cover walls and ceilings with 3/16-in. softboard, or birch

plywood of approximately the same thickness. Use cup washers and oval-headed

screws for attaching the interior finish. Fig. 5 details the window framing.

Only the side-window sashes are hinged; the others are stationary.

On the side windows, screen wire is attached to the inner

side of the outer frame, or casing, before it is screwed in place. The

hinged sashes are held open by a light chain attached to the ceiling with

a screw eye. Trailer-type window units also can be used instead of the

type detailed in Fig. 5. These are furnished as a unit complete with screen

and metal frame ready to install in the window opening. Lintels over the

windows and door are cut from 3/4-in. stock and the top edges are beveled

to form a watershed. The parts are attached to the framing with screws. |

|

|

Top edges of the door and window lintels are beveled

to form drip caps.

|

| The back door is a simple unit made from waterproof plywood.

This is hinged to swing outward and is provided with a night latch. The

novel step-seat, Fig. 1 and the photo below Fig. 3, provides not only a

handy rear step but an extra seat when folded inside. The frame of the

step is built up by bending and welding angles and flat iron together to

form the supporting frame as in the lower right-hand detail, Fig. 1.

The short angles to which the step is pivoted are shaped

as shown by sawing and filing and are bolted to the floor of the center

section. They must be located so that when the step is folded outward the

vertical members of the frame will bear against the outer edge of the doorsill

as in the photo below Fig. 3. Cover the bottom of the step, this forms

the seat when the step is folded, with 1/2-in. waterproof plywood. |

|

|

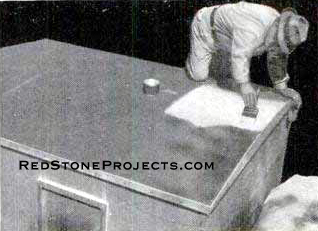

Prime coat the roof, sides, and ends with one coat

of aluminum paint.

|

| No construction details of the interior fittings have

been included, as the arrangement of the cabinets and accessories has been

left to the discretion of the builder. However, the lower left-hand detail

in Fig. 4 suggests a typical arrangement of the interior. If desired, the

center-section floor can be covered with linoleum or rubber tile and the

exposed portions of the overhang on both sides can be upholstered to form

two comfortable seats.

Paint the outside of the body with one coat of aluminum

paint as a primer, then finish with two coats of outdoor enamel in whatever

color you desire. If the inside has been finished with birch plywood, give

it two coats of varnish in the natural color.

The unit should be fastened in place on the truck bed

by two 3/8-in. bolts passing through the floor underneath the bed and through

the metal bed of the truck. Locate the bolts so that they are easily reached

from the underside of the bed and use lock washers to prevent the bolts

from loosening.*** |

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|