Free Shipping on All U.S. Orders

All Orders Processed on a Secure Server

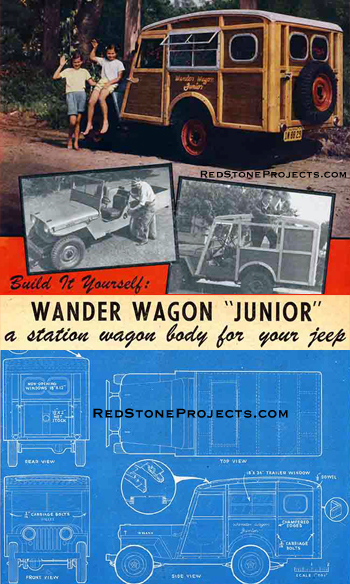

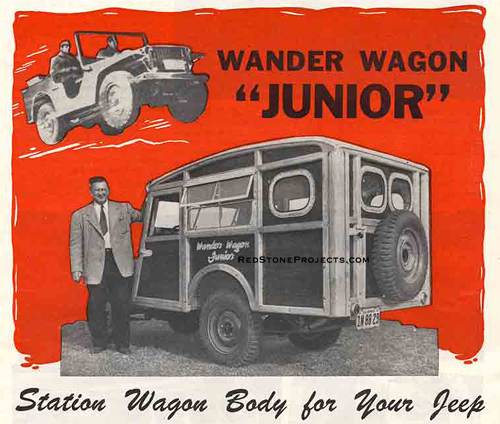

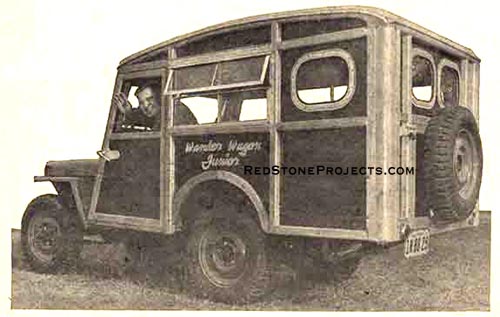

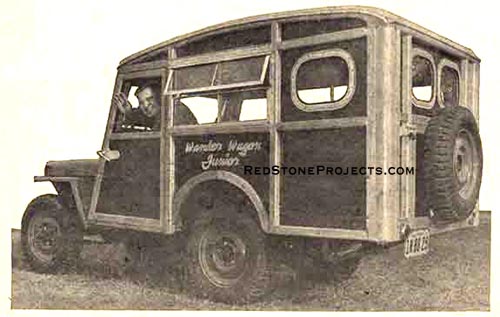

Build a Jeep Woody Station Wagon

Plans for a Vintage Wood Jeep Camper Body

| HERE'S a building project that will dress up that "work

horse Jeep" of yours fit to enter any kind of society. It will not only

look "classy" but will provide the best little outdoor car that any man

could possibly want. |

| Let's take a quick look at what it offers. Interior space

is approximately 5 ft. x 8 ft. and provides on occasion seating for eight

or more persons or full-length bunks for two. Under the rear seat is plenty

of room for complete commissary which can be used either inside in bad

weather or on the tail gate when balmy breezes beckon. |

| There is plenty of storage space for a couple of persons

to travel anywhere there is a faint semblance of a road. And even better

than that - any ex-G. I. will corroborate this - if the rocks and ditches

aren't too big you don't even need a road!

It is a project entirely within the limitations of the

home workshop: even the site equipped with only a good set of hand tools

can produce a good job. However, since most of the lumber is usually purchased

rough, if you are without power tools some preliminary milling will be

necessary. |

|

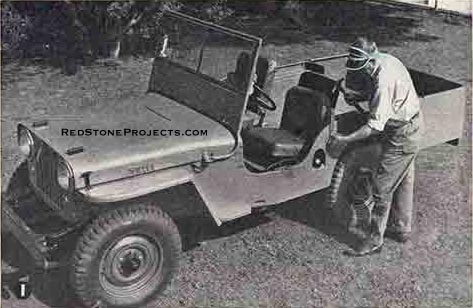

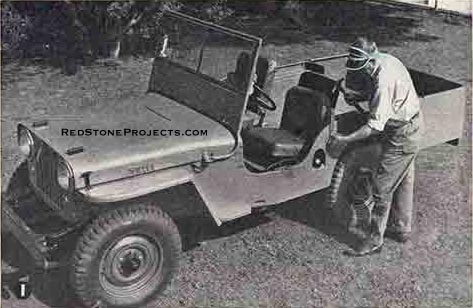

Photo 1. Stripping off protruding metal parts.

|

|

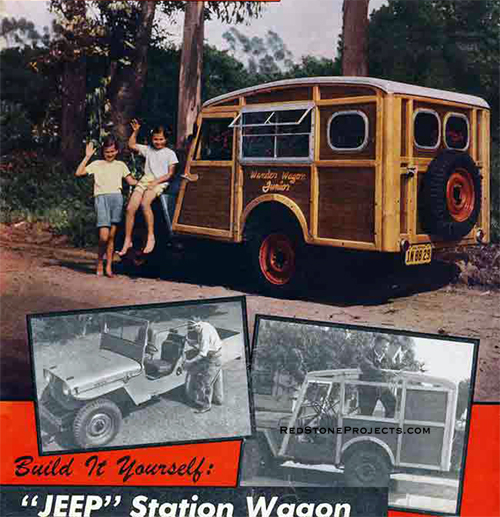

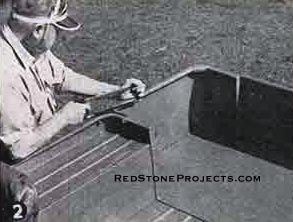

| Junior Wanderer woody wagon was built on a civilian Jeep

chassis, although the military job can be used just as satisfactorily.

In order to get the additional length, a two-foot extension must be built

on the rear of the standard body. Any good metal shop can do the job following

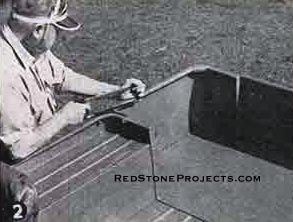

the general plan as shown in Photo 2.

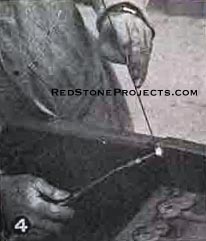

In case you plan to build just like the original it will

be necessary to cut out the metal just above the rear wheel housings as

shown in Photos 3 and 4. Left in, this hump would be right in the middle

of a sleeper's back! For a job which is to have seating capacity only,

this metal cutting is not necessary. |

|

Photo 2. Adding the 2-foot rear extension.

|

|

| Estimates as to the time required to build Junior can

vary, but one man working full time for three weeks could probably do the

job quite easily.

You will note that the designs show a portion of the top

to be convertible, while the photos show it solid. This was done because

the builder plans to carry a boat atop Junior and the convertible feature

could not be used. However, the construction is not too difficult a job

as will he shown in the plans. It is plenty large enough for front seat

occupants to "see the scenery" if they so desire. |

|

Photos 3 and 4. Removing material above rear wheel

wells.

|

| In regard to the extension, the builder who does not

wish the bunk or eight passenger features, can build the same type of body

on the short, regular chassis. The height of the roof can be brought down

about 6 inches in this case as the headroom shown in the plans is necessary

only when passengers are to be seated on cushions atop the wheel housings.

Materials for building can be obtained from any good lumber

yard, hardware store, and trailer supply house, including the double-opening

aluminum windows, oval stationary windows and lock and hinge hardware. |

|

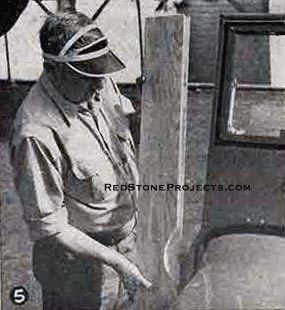

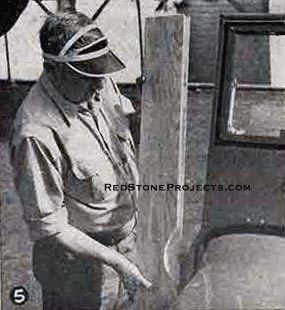

Photo 5. Fitting windshield side pillars.

|

|

| Buts let's get to work. First it is necessary to strip

off all protruding metal parts (Photo 1), so that the body panels can lie

flat. In the civilian model it is relatively simple, a good cold chisel

sufficing, but the military chassis may require some hack sawing or even

torch work. Do not try and cut any flat welded pieces entirely; just notch

out the wall panels slightly to receive their slight projections.

Fitting the pieces around the windshield requires some

nice work. Take the pair of pieces 4 ft. long and 7 in. wide, saw and gouge

out to fit fairly closely along the windshield sides down flush with the

short tail section of fender running board. |

|

Photo 6. Fitting the top windshield crossmember.

|

|

| Allow about 3/16 in. clearance between metal and wood

for the insertion of strips of heavy felt and mastic to waterproof and

squeak proof the joints. This felt and mastic is used whenever a wooden

panel is bolted to the metal body (Photo 11). |

Get a restored copy of these vintage Jeep Woody Wagon

Camper Plans with 18 Pages of Enhanced and Enlarged Figures and

Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

Jeep

Woody Camper Front, Rear, and Side Elevations with Plan View

|

|

When these two side pieces are fitted and bolted with

5/16 in. carriage bolts, cut a piece of 1 1/2 in. x 2 in. stock for the

top gouged out as shown in Photo 6. This is felted, masticed and then doweled

and glued securely to the top edge of the side pieces. (Photo 7 and Front

Elevation.) |

|

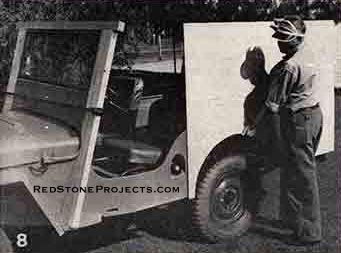

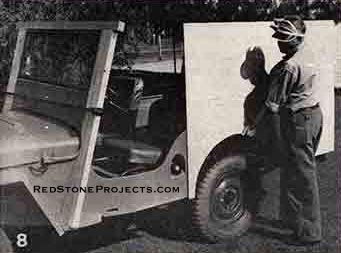

Photo 8. Fitting the side panels.

|

|

| Use a good heavy mix of waterproof glue whenever a joint

is made for Junior.

Along about this point you will probably note the absence

of minute measurements on the plans. These have been left out as each piece

will have to be individually fitted to the slight variations that occur

in each separate body. The original drawings were done 1 in. to 1 ft. and

you can work out your own scale by checking the reproductions against a

known measurement - the side windows, for example, are 18 in. x 34 in.

- and thus calculate rather closely the important dimensions.

Next, take a piece of the 4 ft. x 6 ft waterproof plywood

and hold it against one side of the body as shown in Photo 8. The front

edge becomes the rear framing of your door and in the civilian job comes

just at the rear edge of the gas filler cap. Scribe the arc of the wheel

housing and the slight kickup of the rear extension. Cut it off at the

rear flush with the back line of the body. Plan your side window openings

to come in the top forward corner of this piece.

Then build up a pair of corner angles using four-foot

pieces of stock 4 in. and 5 1/2 in. side as shown in the side elevation

and the detailed circle insert. Glue and dowel well and round off the corners

nicely. These pieces may be rabbeted 1 in. wide and 1/2 in. deep on the

outside center for improved appearance. Check the exact measurements from

the side wall to the edge of the tail gate opening and cut a 4 ft. section

of plywood to fit. |

|

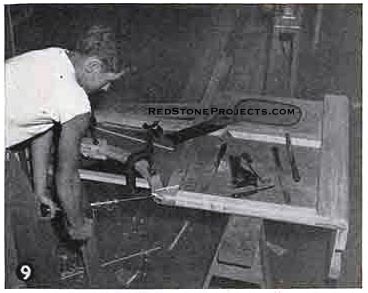

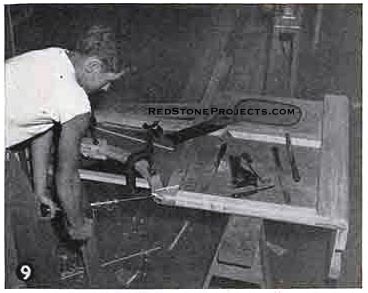

Photo 9. Building up the corner pieces.

|

|

| Take the waste sections in the shop add build up the

framing with the 1 1/2 in x 2 in. stock and the heavy corner pieces as

shown in the drawings and in Photos 9 and 10. The two perpendicular center

pieces should be left long as shown. Use plenty of glue and dowels. Half

lap joints were always used for wooden body construction by old time builders

and you may use them if you desire. However. modern glues and the heavy.

short-span design of Junior makes doweling perfectly satisfactory. |

|

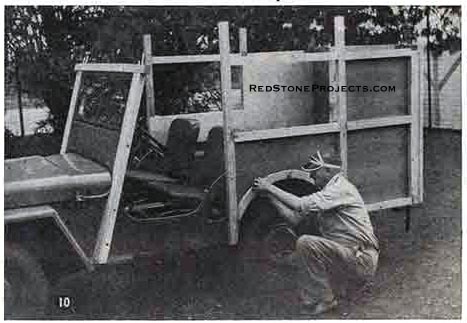

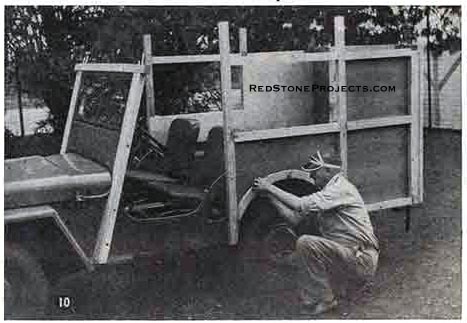

Photo 10. Building up the side framing.

|

|

| In mounting the sides to the chassis use felt strips

between wood and metal and carriage bolts in the place shown. Check the

exact spots before you drill for ease in drawing up the nuts tight and

making the body solid.

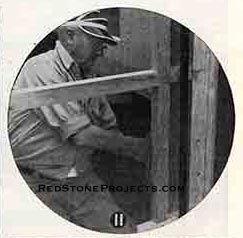

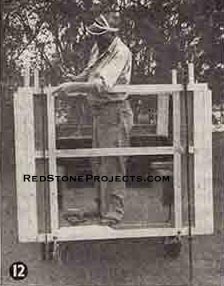

Photos 11 and 12 and the rear elevation show rather clearly

the framing at the rear. The top piece of 1 1/2 in. x 2 in. stock is cut

off to allow for the 1 1/2 in. thick timber which will be used to make

the roof fore and aft arch. |

|

Photo 11 and 12. Rear framing detail.

|

|

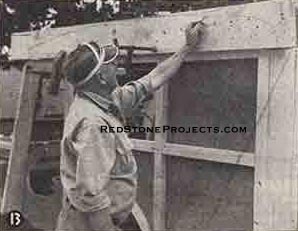

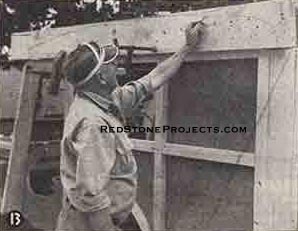

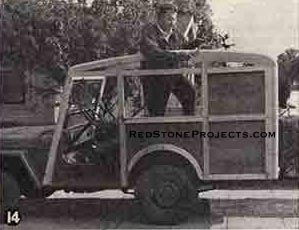

Clamp one of the 1 1/2 in. x 8 in. x 8 in. pieces along

the top of the side as shown in Photo 13 and scribe out the top roof lines.

Standoff at a distance and make sure it looks good. A thin bending strip

held for a marker will help smooth out the lines. Band saw to shape, then

use a

marking gauge to get the lower edge 3" below the top

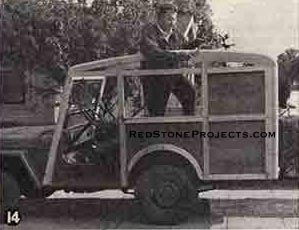

except at the rear where it widens out to 5 1/2 in. Photo 14 shows how

it looks when finished. Try this piece on the other side where it should

fit if you have kept your body all squared up. Cut another similar section

for that side. |

|

Photo 13. Scribing the roof lines.

|

|

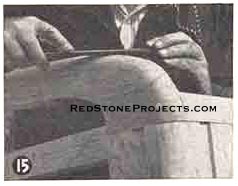

These sections are doweled and glued to the upright timbers

which have been cut at the right angle to take them smoothly. When fitted

they are rounded off with drawknife and wood rasp as shown in Photos 14

and 15. Leave about a half inch on top flat to take the 1/4 in. plywood

roof which in turn is feathered off to make a smooth corner.

|

Photo 14. Rounding the roof line.

|

|

|

Photo 15. Rounding the corners.

|

| Next fill in the longitudinal pieces on each side over

the large side windows and over the doors with 1 1/2 in. stock. Dowel and

glue as before. Take special care in notching out the joint with the windshield

section, as poor work here will result in body creaks later. The finished

Junior developed its only body creak at this point, but this worked out

before very long. Use the scrap pieces of plywood cut from the window area

to fill in the paneled walls of this upper section.

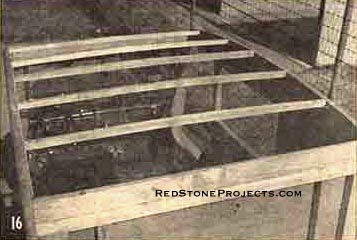

Roof beams am cut of 1 in. stock and crowned 1 in. at

the center. They should finish 1 1/2 in. deep and are bolted with iron

angle braces 2 in. by 2 in. as shown in the detail of the rear elevation. |

|

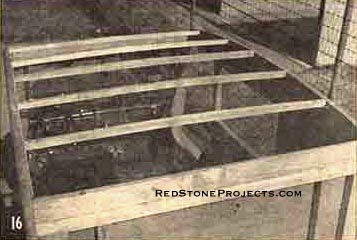

Photo 16. Roof cross ribs installed.

|

|

| By now you will have had everybody and his brother watching

you construct that station wagon body on your Jeep chassis. The unique

appeal and attraction of that compact little job seems to reach out to

all ages. The authentic station wagon lines will draw the attention of

some; the neat, solid looking construction will appeal to others; while

most of them will see in it the chance to really succumb to the wanderlust,

wherever and whenever it might lead.

We left off with you installing the cross ribs for the

top. When this is done take some short scraps and cut three pieces to fill

in between the last rib and the rear and the first rib and the front. See

top elevation. These are cut on the same arc as the corresponding portion

of the side timbers and are necessary to give the quarter-inch plywood

roof some additional center support where it is given quite a sharp bend. |

|

Photo 17. Installing the roof.

|

|

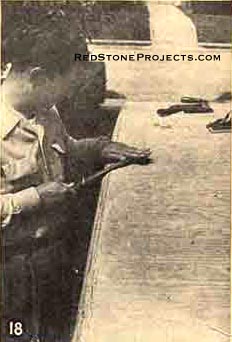

| The top is made of two pieces of fir plywood 4 ft. x

5 ft. The joint is made on the center rib where it is glued and screwed

with No. 6, 3/ 4 in. flathead screws every 4 inches. There is a slight

compound bend required here, but as the cross bend is only an inch it will

give no trouble. The plywood need not be soaked to take the bend.

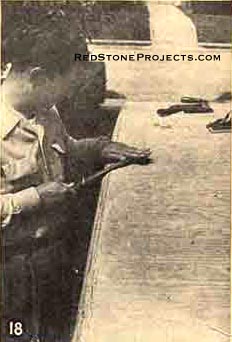

Work from the center each way, fastening with glue and

screws to each rib, see Photo 17. Where the roof plywood meets the side

timbers you may substitute galvanized or cement coated 4 penny nails spaced

every two inches. When the roof is all on this edge, feather off as shown

in Photo 18 and as you work with a rasp each nail can be pounded in a little

further, if necessary, so as to stake the corner nice and rounded. |

|

|

Photo 18. Feathering

the roof edges.

|

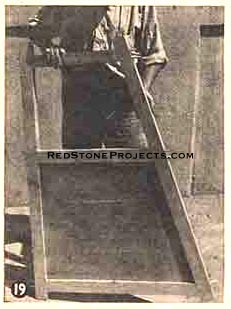

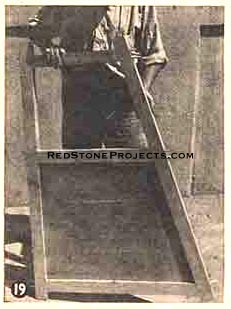

Photo 19. Door construction.

|

|

| In making a smooth roundoff at the front and rear it

will be necessary to fill in another piece of 1 1/2 in. stock beveled at

an angle according to the top curve. This in turn is drawknifed off nicely

and the roof plywood fastened to it. If you don't mind a sharper corner

this extra piece can be dispensed with and the roof plywood brought down

to the crosspieces already in place. It won't look as well, however, as

it will with the extra piece as the bend is too sharp for 1/4 in. plywood.

These pieces are shown in the top and side elevations. |

|

Photo 20. Door and window construction.

|

|

If you are making the convertible feature the hole should

be cut in now before the top covering is on although it can he added at

any time after the entire job is finished. Follow the drawings as shown

in the top elevation and in the detailed circle shown in front of the side

elevation. It is built like a box lid that goes over another box. A little

difficulty will be encountered because of

the arch in the roof beams but if the pieces around the

top opening are built up so they are flat on their upper edge, and then

the cover is built flat, hinging will be simple. |

|

Photo 21. Door stops and weather stripping.

|

|

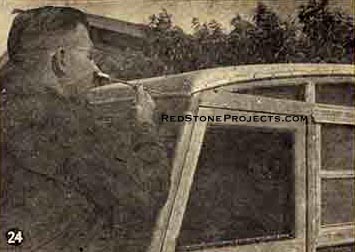

The top should be covered after the hole is cut but before

the box sections are put in. A sheet of cotton batting, obtainable in any

dry goods store, is spread out over the entire top. This batting semi-insulates

the roof and smooths out any inequalities you might have left in the plywood.

Over this is stretched the canvas which is tacked around the edges with

copper tacks. Make it as smooth as possible but don't worry too much if

it isn't perfectly smooth as the finish painting will stretch it nicely.

Tacks should come every 2 in. around the entire top. These are later covered

with the aluminum drip molding as shown in Photo 24. At the convertible

opening the cloth is drawn down and tacked to the sides of the ribs over

which the border pieces are screwed. Use plenty of mastic under these to

keep out the water. Several coats of airplane dope on the canvas will shrink

it tight and waterproof it. A finish coat of aluminum paint looks well.

Next come the doors and the tail gate. Photos 19 and 20

show closeups of the door and window construction while Photo 25 shows

a closeup of the tailgate. For the doors, first make a cardboard or scrap

plywood template of the opening. On this mark the line of the longitudinal

middle piece of the body side and build the door over this as a pattern.

It is made of regular 1 1/2 in. stock and the door panel is rabbeted in

3/4 in. from the outside. This inside space will allow for the fold-down

window. A crank type window can be installed if desired but in this case

the door panel should be set in only 1/4 in. so as to allow space for the

winding mechanism. Salvage parts for its operation can he found in auto

junk yards.

|

|

|

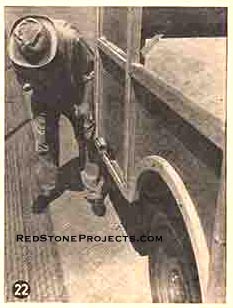

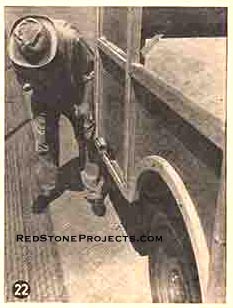

Photo 22. Chamfering the frame.

|

Photo 23. Stationary window frames.

|

|

| Hinge the door with the continuous hinge allowing 1/4

in. space for sponge rubber stripping. Stops of 1/4 in. plywood 1 1/2 in.

wide can be fitted at the top and rear edges while the front and lower

edges must be stopped with 1/2 in. square sections of material. See Photo

21. Install the hardware for handles and latch carefully as nothing is

more irritating than a car door which doesn't work perfectly.

Before the windows are installed the entire outside of

the frame sections are chamfered for improved appearance. If you have access

to a portable shaper, you're in luck, but the job can be done with a chisel

and a lot of patience. See Photo 22.

The large side windows are easy to put in. Your openings

should have been made to fit perfectly so a liberal amount of mastic and

3/4 in. roundhead brass screws every 3 or 4 in. will make a tight fit.

The stationary windows are first framed with some scrap pieces of waterproof

plywood as shown in Photo 23. One inch roundhead brass screws go through

the metal window frame, through the outside plywood frame, through the

plywood wall which has been keyhole sawed out to fit, and into the plywood

inside frame which finishes off the window inside. If you get a different

type of stationary window than the one shown just adapt the installation

to fit. |

|

Photo 24. Installing aluminum drip molding.

|

|

| The door windows are made of 5/16 in. plexiglass hinged

at the bottom with a 3/4 in. continuous hinge as shown in Photo 20. Button

catches, as shown, hold the window closed against the rubber weather stripping

and also hold it from rattling when folded down. See Photo 21.

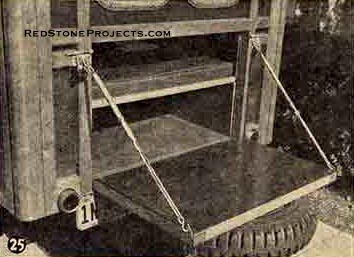

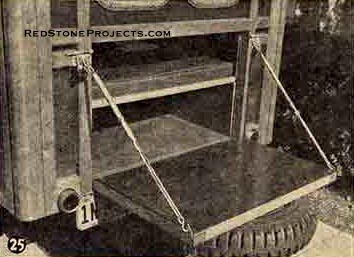

Tailgate construction and operation is shown in the rear

and side elevations and in Photo 25. The frame is built up with 1 1/2 in.

stock, doweled and glued and faced with the body plywood. A reinforcing

piece of 1 in. maple about 8 inches wide should be let into the framing

just behind the plywood if the spare tire is to be carried on the rear

as shown on Junior. The tire rack is the same one that comes as regular

equipment on the side of the civilian jeep chassis. |

|

Photo 25. Tailgate with hardware.

|

|

| The tailgate is hinged at the bottom with the balance

of the 1 1/2 in. continuous hinge and stops installed on the inside of

the body to hold the rubber weather stripping against which the gate closes.

Locking type slide bolts are fitted to hold the gate shut. See Photo 25.

Two sections of chain are fitted with S hooks on each end for supporting

the gate when down. They are completely removed when the gate is closed

so as to eliminate any chance of rattle while traveling. |

|

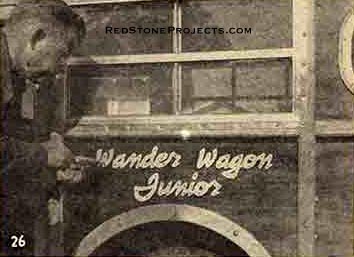

Photo 26. Applying the Wander Wagon Logo.

|

|

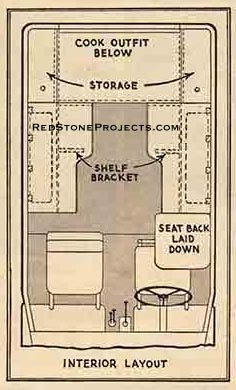

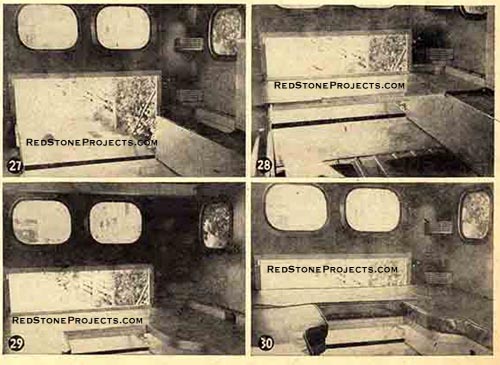

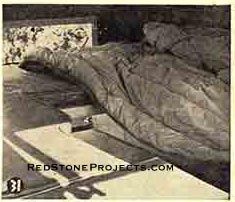

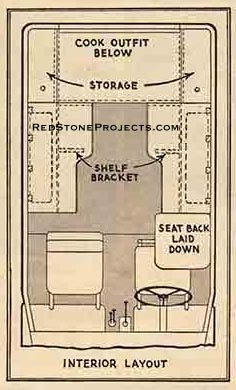

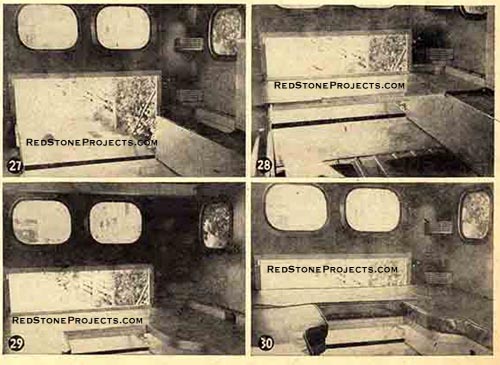

| The interior layout and Photos 27 to 32, inclusive, show

how Junior can be made to bunk two persons and seat seven or more in the

cab. One 4 ft. x 8 ft sheet of 3/8 in. plywood will make the necessary

pieces. Of course, any type of cross seating arrangement can be used to

suit the builder's fancy but the one shown makes a real "Wandering Wagon"

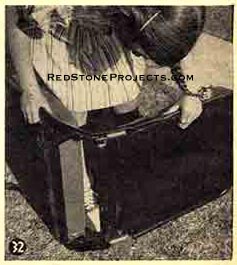

out of the job.

First cut the seat backs off and replace with a machined

stem to fit which is brazed to the lower section. Photo 32 illustrates

this. When the bunks are made up, the seat backs are slid off the stems

and are laid flat to take the sleeper's feet as shown in the photos.

First cut two pieces of 3/8 in. plywood to extend from

the front of the wheel housings to the tailgate opening, the height flush

with the top of the wheel housings. See Photo 27. Block in the sides of

the metal body just under the rolled top edge with 1 in. stock screwed

through the metal into the wood. Fit a piece 24 in. wide, cleated front

and back, that will just fit the top edges of the longitudinal pieces.

The cook box goes under this. In each corner, fit a loose piece on side

cleats. This piece can be removed to get into the storage compartments

underneath. See Photo 28.

The side pieces are curved as shown with a thin plywood

lip on the outer edge to retain the cushions and hinged against the walls.

A heavy shelf bracket is bolted to these pieces for extra support when

used as a seat. |

|

Jeep Woody Interior Layout

|

|

| Latex cushions, made to order by any large mattress factory

or store, are most satisfactory although good cotton or kapoc pads will

suffice. |

|

Photos 27 through 32. Interior arrangements for

seating and sleeping.

|

|

| The cook has is made to fit the opening under the rear

seat and is approximately 2 ft. x 4 ft. x 10 in. deep. I put a built-in

ice box in mine, but a removable factory-made box is quite satisfactory.

This box can be used either on the tailgate in good weather or inside for

"Jupe Pluvius".

Racks and shelves for fishing rods, guns, etc., can be

installed wherever desired on the walls. A dome light placed as shown in

the top elevation comes in mighty handy. |

|

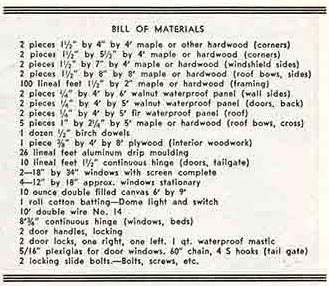

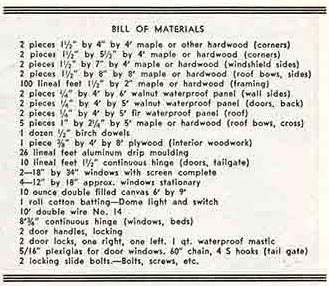

Wander Wagon Junior Bill of Materials

|

|

| Outside finish should be two coats of shellac, well rubbed,

and two coats of good quality spar varnish. One coat of shellac and two

of varnish are sufficient for the inside. The outside should be redone

twice a year or oftener if exposed to much inclement weather. |

|

Completed Wander Wagon Junior

|

|

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|