Free Shipping on All U.S. Orders

All Orders Processed on a Secure Server

Vintage Calico Truck Camper Plans

Uses Lightweight Wood Laminate Construction

|

Vintage Calico Truck Camper Plans

Uses Lightweight Wood Laminate Construction

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these Vintage Calico Truck

Camper Plans with 11 Pages of Enhanced and Enlarged Figures and

Illustrations and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

|More

Vintage Trailer Plans|

|

|

|

|

Start a Rebellion

Build a Calico Camper

Looking for a camper the breaks away from the overweight,

oversize, tin-box syndrome?

Build this one yourself.

By W. B. Breyer

|

|

|

Instant back porch appears when you when

you lower the tail gate, a handy feature in a muddy campsite. Those large

drawer pulls on the on the back of the camper are handholds to help you

make the big step from the ground to the tailgate.

|

| I've always wanted a truck camper. But to my mind most

of the rigs I see on the road are too big, too heavy, too expensive - and

just plain boxy. So, I rebelled and built my own. Its light weight and

low wind resistance make it fun to drive. Its "Calico Conestoga" look

draws stares wherever I go, and that makes it fun to drive too.

The design is simple. Laminated redwood ribs arch across

the truck bed every 16-in. like top bows on a covered wagon. Over this

you apply plywood wall paneling, good side in. This pre finishes the interior.

Over the paneling I applied cotton duck in a flower pattern, plus fiberglass

cloth and polyester resin. If you don't want a flower-power model like

mine, just leave off the cotton duck. |

|

|

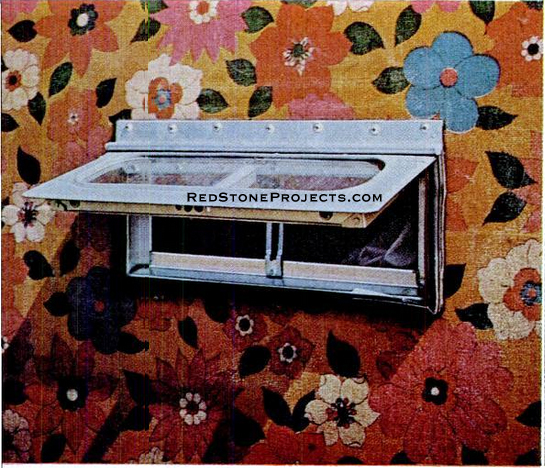

Roof vent/skylight can be opened from the

inside to provide ventilation on a hot day. Here it's installed between

the fifth and sixth ribs, but can just as easily go farther forward, between

the fourth and fifth ribs, if you like.

|

| In my case, the camper is only a shell. You could build

in stove and sink, but this limits interior space to one function. My interior

additions are just a pair of 30-in mattresses mounted crosswise up front.

Side-by-side, they provide queen-size comfort. Stacked, during the day,

they form a davenport and make room for a foursome of cards at night. When

I'm not camping, I lift the beds out and have the entire truck bed to haul

my tools.

You build the camper by constructing subassemblies for

ribs, sills, back wall, matins, and overhang. All assemblies fit through

a standard door, so you can start work in your living room if you have

to. |

|

|

|

Unique is the word for the Calico Camper.

From its unusual profile to its flowered exterior, it's like nothing you've

seen before. Slanting cab overhang and rounded corners cut wind resistance

for easy cruising and good gas mileage. The camper is so light, it barely

affects handling. You'll probably leave it on the truck even when you're

not camping.

|

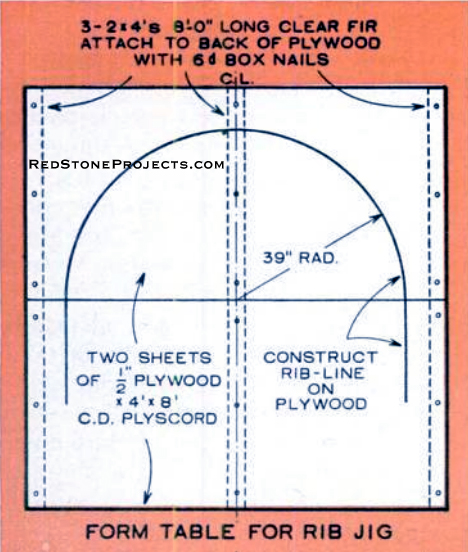

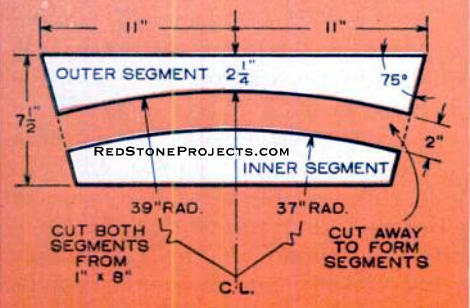

| Begin with The Ribs

Each of these is laminated from eight thin strips of redwood;

the only stuff I could find clear enough to bend without breaking. Fur

accurate bends. you'll need to make a laminating jig, the accompanying

drawings show you how. The plywood and 2 by 4s that make up the jig are

later used as parts in the camper's rear wall and front overhang.

For my truck, a '69 Ford, the outside rib radius is 39-in.;

you may have to modify the jig for your truck. To determine the inside

radius, subtract the thickness of a rib from the outside radius. In my

case, the eight rib plies added up to a total thickness of about 2-in.

This made my inside radius 37-in., so I cut the inside jig forms to that

radius.

Before you laminate a rib, smear some paste wax onto the

jig. The wax acts as a parting medium so you can remove the ribs easily

once the glue dries. Brush glue onto the rib plies, leaving the two outside

faces bare, and place the plies on the jig. Starting from the center of

the curve and working out in both directions, clamp the outer forms in

place.

While you're waiting for the glue to dry, work on the

sill assembly and the front and back walls. Before you start framing, though,

you'll need to know your window sizes. I used ordinary storm windows in

the door and the wall behind the cab. Side and front windows are 6-in x

14-in. trailer units made by If Hehr Mfg. Get them at a trailer parts store.

While you're there, pick up a 9-in. x 9-in. roof vent with screen. |

|

|

Side windows are small enough to fit between

the ribs without framing modifications. Mounted 18-in above the sills,

they provide plenty of head and foot ventilation while you sleep. The same

type of window is used in the in the cab overhang.

|

| Make the sills and front wall from a sheet of 3/4-in.

AC exterior plywood. Keep the good side up and out wherever applicable.

Glue and screw all joints and half-lap the sill joints. Cut a 3/4-in. x

3/4-in. rabbet along the bottom edge of the front wall and fasten to the

sill assembly.

The Back Wall

Here you need two new sheets of 1/2-in. CD Plyscord. Rout

a half-lap joint on one long edge of both sheets, keeping track of the

faces on the two C sides will be on the outside. Glue the two sheets together

and tack with brads to hold while the glue dries. Keeping the lap joint

vertical, lay out the curved shape (same as the rib curve) and saber-saw

the wall to size. When you've bent the last of the ribs, use the jig framing,

ripped into 2 by 2s, to Frame the rear wall. Glue, nail, and half-lap all

joints. |

|

|

Clearance lights at the front corners of

the camper are an aid for nighttime maneuvering in unimproved campsites.

Note the extruded aluminum trim with plastic insert that's run around the

edges of the camper. It's sold by trailer dealers.

|

|

Figure

1. Calico truck camper assembly with dimensions.

|

Get a restored copy of these Vintage Calico Truck

Camper Plans with 11 Pages of Enhanced and Enlarged Figures and

Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

| Purlins and edge nailers provide spacers that hold the

ribs at proper intervals, and supply blocking between ribs to nail the

edges of the paneling to. Glue and nail the blocking to the purlins. The

blocking should be cut slightly wider than the thickness of a rib, then

planed down, flush with the ribs once the camper framing has been assembled. |

|

|

Form Table for Rib Jig

|

| Now to go to work on the overhang. Use the two sheets

of plywood from the bending jig, plus another sheet of 1/2-in. Plyscord.

One sheet from the bending jig is cut to the rib radius and forms the wall

of the overhang. The other makes the floor of the overhang. and the Plyscord

forms the slanting nose member. When you've got the overhang roughed into

shape, you are all set to start putting everything together.

Place the sill assembly on a pair of horses, or on the

truck bed. Fasten the rear wall to the sill and attach some temporary bracing

to hold the parts at right angles. Attach the ribs at proper intervals,

running screws up through the sills into the blocking between the gussets.

Run a tape measure from the bottom of a sill up along

each rib and mark the ribs at 48-in., 98-in., and 144-in. Attach the purlins

at these points, making sure the blocking is centered on the marks. Now

plane the blocking flush with the ribs and install the framing for roof

vent and windows.

At this point, set all nails, and spackle all nail and

screw holes. Sand everything that needs smoothing. and seal the framework

inside and out with shellac. If you want to leave the ribs natural, varnish

them. Then paint everything else but the outside of the slanting nosepiece.

This will be glassed later, as bare wood gives better adhesion. |

|

|

Rib Clamps

|

| Next Comes the Paneling

Be sure to use plywood paneling, not the type made from

hardboard. Apply a thin ribbon of panel adhesive to the tops of the ribs,

the edge of the sill, and the edge of the blocking. With the good side

in, start a sheet of paneling at the sill. I used ring-shank drywall nails

at the sill and rear wall, and anodized Ardox spiral nails into the ribs. |

|

|

Rib Laminating Jig

|

| Nail up along the ribs, folding the paneling into the

curve as you go. Don't cut out the window hole; that only makes for problems

when you start to fiberglass. Finish the panel by nailing into the edge

of the blocking. I nailed close; 2-in. or 3-in. apart, at points of high

stress, and about 8-in. apart going up the straight section of the ribs.

Now move on to the second panel, cutting it out to fit

around the roof-vent framing. Apply the third panel, and finally rip the

fourth panel to size (about 15-in. wide) and nail it in place.

Glue and bolt the overhang onto the front rib, using the

stove bolts from the rib jig. With a rasp, fair the edge of the curved

slanting portion of the nosepiece to the proper angle to receive the paneling.

The leftover portion of the fourth panel provides more than enough material

to cover the sides of the overhang.

Adding the "Flower Power"

This is pretty much standard boat-glassing procedure.

The only difference is the decorative cotton duck that goes on before the

fiberglass cloth.

After glassing, cut out the window openings. If you use

power tools, keep in mind the fact that fiberglass dust is highly abrasive

to motor bearings, not to mention your lungs. Be sure to wear adequate

breathing protection. Now you can set in all the windows and the roof vent.

Trim around the bottom of the back wall where the wall

fits inside the truck box with 1-in. aluminum angle. This will prevent

splintering when mounting and unmounting the camper. I trimmed all exterior

edges with aluminum molding, the kind with a plastic-bumper insert. It

cost me 22 cents a foot at a camper parts store.

Before installing the camper on your truck, stick plastic-foam

seal under the sills where they contact the box. You may need a double

layer in some places if your truck box isn't perfectly level around the

top.

When the camper is in position on the box, hold it in

place with C clamps and drill eight evenly spaced 3/8-in. holes down through

the sills and lip of the truck box (four on each side). Slip drilled scrap

blocks under the truck-box lip to prevent metal distortion, and bolt the

camper in place with 3/8-in. bolts. Seal the rear wall of the camper inside

the truck box with furnace-duct tape.

Although Michigan law doesn't require clearance lights

on a truck under 80-in. wide, I added several as aids in maneuvering around

unimproved campsites in the dark. Check the requirements in your state

before you hit the road. |

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|