DIY Tent Trailer

Trailer Articles

>

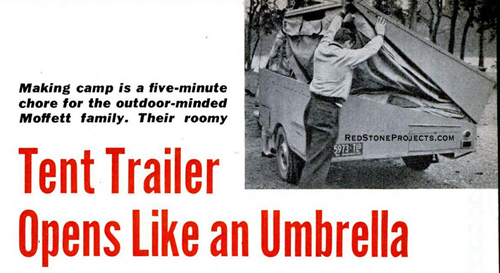

DIY Tent Trailer Opens Like an Umbrella

|

GOING camping, Bob Moffett believes, is the best way in the world to spend a summertime weekend. His wife Lorraine thinks so, too.

Their three youngsters, boys aged 10, eight and three, all approve. It's just a few hours drive from their home in Tacoma, Wash.,

to the ocean side, to long, empty stretches of beach where green Pacific surf washes the sand, and a sheltered camping site where they

can build a driftwood fire and bake a salmon. A week later they can travel inland, following roads winding up through forested

slopes to an alpine park somewhere in the coastal mountains.

|

|

|

|

|

That's living, say the Moffetts. There's only one catch. These family-sized camping expeditions used to involve too much cargo handling. Tent, tools,

sleeping bags, food, cookware, coats, hats, popguns! The car would be so full by the time the family was ready to leave that Bob practically had to

grease the kids and wedge them into the back seat feet first. Travel, under these conditions, was a pretty rugged deal.

Setting it up. After cogitating a bit, Bob planned and built what amounts to a split-level, weekend home on wheels. When his wife sees a spot to camp somewhere along the highway, Bob

can set up outdoor housekeeping faster than the sprouts can scamper out of earshot with their popguns.

|

|

|

|

|

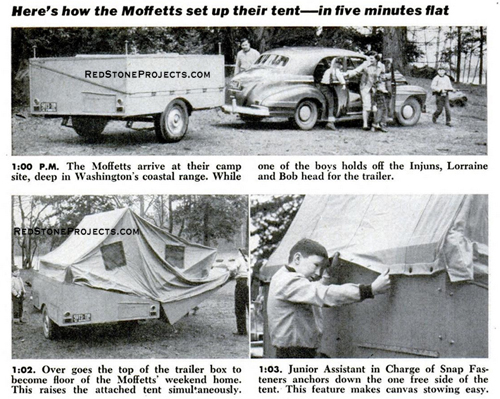

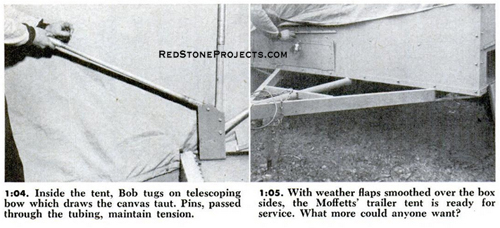

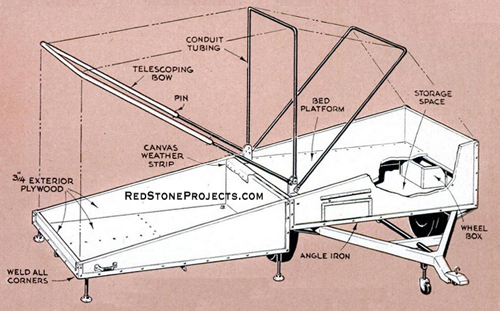

He simply opens the two section trailer box.

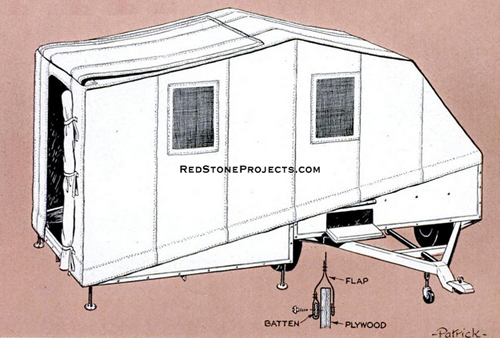

As the top section swings over on its hinges, out comes the canvas tent. And as the tent unfolds, three bows made from rigid

conduit tubing pivot up to support it. Then, Bob slides out the telescoping front bow to tighten the canvas. That's it!

Parlor and bedroom. Opened out, the two sections of the trailer body become the floor of the tent. The area just inside the door is roomy enough

for indoor eating should the weather turn damp. Beyond, on the shelf covering the storage compartment, there's a fullsize bed mattress, covers all ready

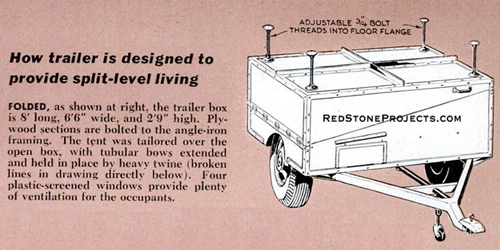

for sleeping in. George Pullman couldn't have done better. Dimensions? It's pretty much a cut-and-fit proposition, Bob says. The body of his trailer turned out 8 feet long (the

length of standard plywood sheets), 6 and a half feet wide, and 33 inches high.

|

|

|

|

Building the chassis. Bob could have bought a second hand trailer chassis and gone on from there. Instead, he built his own chassis from structural steel and junked auto parts.

He cut and welded two 3 inch channels for bed rails, then set in heavy angle steel crosspieces. For the axle, he scrounged a piece of tubing from an ancient car, cut it to length,

and welded plates and front wheel spindles to the ends. Leaf springs, which hang from shackles welded to the channels, carry the axle. Just for good measure, Bob bolted in a pair

of shocks.

He found that the easiest way to build the body was to weld up the angle-steel framework first. Then he hacksawed it into two parts. This done, he could cut the

plywood panels to fit inside the angles. Before bolting the body together, he cut openings for storage compartment doors.

To throw some weight on the trailer hitch, Bob says, the trailer body should be mounted with its centerline one inch ahead at the axle.

The big top. Sewing together the tent proved the trickiest part of building the trailer. Bob could have used anything from plastic-impregnated fabric to

close-woven nylon poplin. He settled for ordinary cotton duck, the least expensive.

You'11 never know how to sew a tent together until you've done it, Bob maintains. When you measure the trailer, raise the bows and tie them in position. Loop the canvas over them,

pinning it temporarily, and then machine-stitch the seams. Worry about the details as you come to them.

That's about all the advice Bob has to offer anyone who wants to tackle this kind of a camping rig.

"Except," he adds, "a recommendation that you check your home state's licensing requirements before you hit the road. Oh, yes, if you should happen to see another

trailer tent somewhere along the highway - one very much like yours - don't fail to wave 'Hello' to the Moffett family.

|

Trailer Articles

> DIY Tent Trailer Opens Like an Umbrella

|

| |